Injection Molding Biocompatible Fluoropolymers For Medical Device Industry

Biocompatible Fluoropolymers And Advances In Injection Molding These Materials For Medical Devices, Drug Delivery Systems And Storage Components

Abstract

Injection molded fluoropolymers provide the chemical resistance and material performance needed for the manufacturing, storage and delivery of next generation cancer and biologic drug technologies. Fluoropolymers barrier properties, thermal properties and low surface adhesion characteristics offer advantages for powder and viscous liquid manufacturing, storage and delivery components.

In the past, fluoropolymer were not often considered for high volume parts with complex geometries due to injection molding process limitations. Developments in mold design and tooling steels combined with new manufacturing equipment and processing techniques now allow the use of these biocompatible materials for high volume drug storage and delivery components.

Introduction

Polyethylenes, polypropylenes and polycarbonates currently used for drug storage containers and delivery components will struggle to meet future efficacy requirements. Next generation drug technologies are bringing new handling and dispensing challenges because of increased chemical resistance and cytotoxicity issues. Long-term storage solutions that maintain performance and extend shelf life will be required. Improvements in dosage control and minimizing or eliminating the use of silicone coating operations in drug delivery components have also become industry wide concerns. Because of the elimination of traditional injection molding process limitations, product design engineers can now cost- effectively use fluoropolymers inherent material property benefits to address these issues.

Fluoropolymer Material Benefits

Fluoropolymers are chemically inert and pure generally containing no additives that could contaminate liquids or solids during storage or delivery. Fluoropolymers barrier properties resistance to chemical, enzyme and microbiological attack also eliminate biodegradation issues.

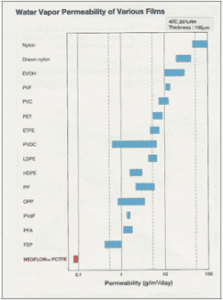

Figure 1. Barrier Properties of Thermoplastics

Compared to current plastics, the barrier properties of fluoropolymers (Figure 1) are exceptional. Aging, even at high temperatures and in the presence of solvents, oils, oxidizing agents, ultraviolet light and other environmental agents, is minimal because fluoropolymers do not use any leachable or degradable stabilizing additives. Fluoropolymers also have a low refractive index and visual appearance that is unchanged after exposure to light. Applications include drug containers and delivery systems components including bottles, vials, syringes and specimen trays.

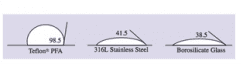

Figure 2. Low Surface Energy Material Comparison

Fluoropolymers have one of the lowest coefficients of friction of any solid material (Figure 2). Low surface energy in its solid state provides an anti-stick, non-wetting contact surface that is hydrophobic and completely resistant to hydrolysis. For sprays and inhalers, fluoropolymer manifolds can minimize drug delivery buildup to assure consistent dosing. Other applications include medical devices, surgical equipment, syringes, plungers, valves and connectors.

Fluoropolymer Processing

Concerns about fluoropolymer material application and processing limitations are prevalent. It is still generally thought that sintering or machining are the only viable alternatives because of corrosion and thermal issues during the traditional injection molding process. Temperatures of molds and equipment can range from 300°F to 800°F.

Highly toxic gases produced have an extremely corrosive effect on both molds and machines. Mold deterioration, runner system scrap rates, melt fracture, delamination and dimensional limitations of traditional gating methods. New fluoropolymers, processing equipment and manufacturing methods have been developed to address both by-product and material waste issues.

Continue reading by clicking, Performance Plastics white paper on fluoropolymers for the medical device industry or contact us to learn more.