Performance Plastics continues to add more capabilities that allow them to push the limits of tolerance control. A 165 Ton Sodick GL150A with Ultra-Precision Repeatability, was just installed at Performance Plastics facility in Cincinnati, Ohio. The 165 Ton Sodick GL150A, achieves high speeds and pressures up to 500mm/sec and 49,700 psi. High response injection is one of  the most important characteristics in critical molding applications. The machine’s low mass/ low inertia plunger is directly responsible for its quick deceleration and ultra-precision control. The exceptional speed of the controller provides real time response during injection and records the melt cushion in 0.001″ for accurate process stabilization. This new Sodick machine will allow Performance Plastics to continue to push the limits of High Precision Molding with their “Problem Solved” approach. Below are some of the features this machine provides:

the most important characteristics in critical molding applications. The machine’s low mass/ low inertia plunger is directly responsible for its quick deceleration and ultra-precision control. The exceptional speed of the controller provides real time response during injection and records the melt cushion in 0.001″ for accurate process stabilization. This new Sodick machine will allow Performance Plastics to continue to push the limits of High Precision Molding with their “Problem Solved” approach. Below are some of the features this machine provides:

-

- Up to 500 mm/sec 19.69”/sec) speed

- Up to 343 MPa (49,750 psi) pressure

- High dosing accuracy combined with an ultra-repeatable process

- Quick response in injection acceleration & deceleration

- Reduced shear melt vs traditional Injection Molding Screws

- Shot usage from 10% of total shot or less vs 20% for traditional Injection Molding Process

- Backflow prevention

“Performance Plastics has been a targeted prospect for Sodick Injection Molding machines by Plustech Inc. for some time due to a similar mindset. High temperature materials, complex geometry applications, along with micro “feature” parts can be difficult if the right machinery and personnel are not in place. Once both of our engineering teams collaborated on a challenging application it was then when we began our relationship. Performance is a company that has the capabilities to work on the high end of the technology curve and we look forward to continue to work and grow with the Performance Plastics team.” Len Hampton, Sodick National Sales Manager

“Purchasing the Sodick GL150, was an easy choice for us. We have worked with Sodick for several years. Their sales staff knew we were looking for a machine to take our abilities to the next level. The GL150 gives us that, increasing our maximum pressure by 33% over our current capabilities. Sodick provided our team with extensive training, making sure this new technology was fully implemented within our systems and facility. The Sodick GL150 gives us one additional tool in our arsenal to push our limits and to create solutions for our customers.” Chris Lawson, Performance Plastics, Chief Operating Officer

About Performance Plastics

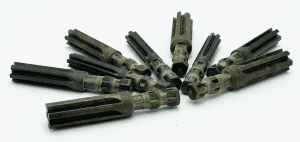

Performance Plastics is a Cincinnati based precision injection molder founded in 1982. Performance Plastics design and manufacture injection molded parts made with ultra-high-performance plastics, specializing in complex geometries and tight tolerances for critical applications. For more information visit www.performanceplastics.com or contact Rich Reed, Vice President of Sales and Marketing, at (513) 321-8404 or [email protected].

Performance Plastics specializes in precision injection molding of high-performance plastics. Our precise production process gives us the ability to injection mold difficult polymers, producing high quality thermoplastic products.

Performance Plastics specializes in precision injection molding of high-performance plastics. Our precise production process gives us the ability to injection mold difficult polymers, producing high quality thermoplastic products.