High performance injection molded plastics have been replacing metal in various applications. The transition from metal to high performance plastics has given engineers more freedom in their designs, while also increasing their products durability. The use of high-performance plastics has created more opportunities in the aerospace, automotive, electronic, and energy industries. High-performance plastics have not only allowed these industries to decrease the weight of their products, but also helped to create smarter products.

High performance injection molded plastics have been replacing metal in various applications. The transition from metal to high performance plastics has given engineers more freedom in their designs, while also increasing their products durability. The use of high-performance plastics has created more opportunities in the aerospace, automotive, electronic, and energy industries. High-performance plastics have not only allowed these industries to decrease the weight of their products, but also helped to create smarter products.

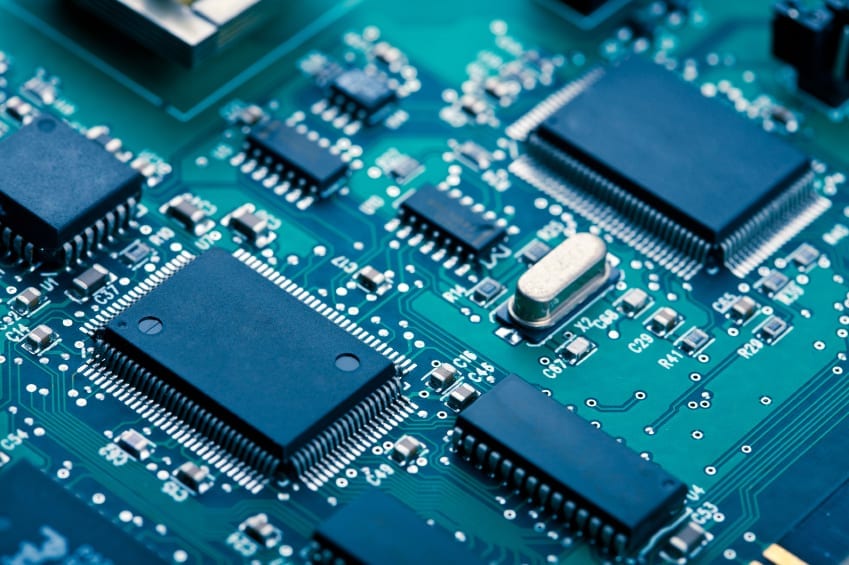

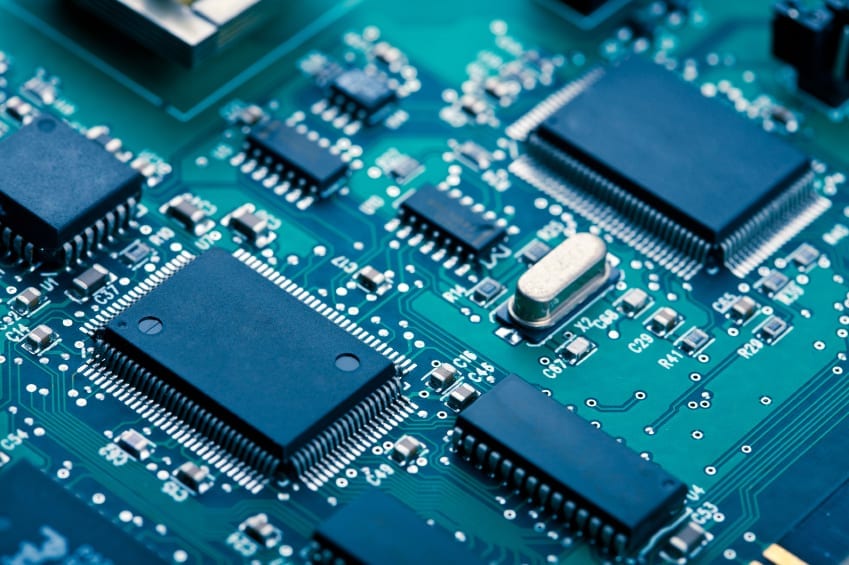

The use of high-performance plastics over metal has been increasing efficiency, but what about the use of high-performance plastics with metal? The use of high-performance plastics, such as PEEK and FEP, with conductive additives including graphite and boron nitride has created a vast amount of new opportunities. Integrating plastic polymers with metal components will still give a lighter, durable product, but it also opens an innovative  range for thermal management. The increase in thermal management allows for improved heat sinks and heat removal applications, creating enhanced performance and reliability.

range for thermal management. The increase in thermal management allows for improved heat sinks and heat removal applications, creating enhanced performance and reliability.

Modifying plastic to improve thermal conductivity has been producing cutting edge products in many industries. These thermally conductive polymers have solved engineering problems for circuit boards, electronics, Li ion batteries, smart phones, appliances and even industrial equipment used in corrosive environments.

For more information on injection molded thermally conductive polymers contact Rich Reed, our Vice President of Sales and Marketing, at (513) 321-8404 or [email protected].

High performance injection molded plastics have been replacing metal in various applications. The transition from metal to high performance plastics has given engineers more freedom in their designs, while also increasing their products durability. The use of high-performance plastics has created more opportunities in the aerospace, automotive, electronic, and energy industries. High-performance plastics have not only allowed these industries to decrease the weight of their products, but also helped to create smarter products.

High performance injection molded plastics have been replacing metal in various applications. The transition from metal to high performance plastics has given engineers more freedom in their designs, while also increasing their products durability. The use of high-performance plastics has created more opportunities in the aerospace, automotive, electronic, and energy industries. High-performance plastics have not only allowed these industries to decrease the weight of their products, but also helped to create smarter products. range for thermal management. The increase in thermal management allows for improved heat sinks and heat removal applications, creating enhanced performance and reliability.

range for thermal management. The increase in thermal management allows for improved heat sinks and heat removal applications, creating enhanced performance and reliability. The aerospace industry has seen a lot of change this year. Effects of Covid-19 keeping planes on the ground and the push to move to a zero-waste philosophy has created a new perspective. The need to watch budgets and recycle all parts of the plane has become a greater priority. This change is increasing aircraft maintainers need for non-marring aircraft maintenance tools.

The aerospace industry has seen a lot of change this year. Effects of Covid-19 keeping planes on the ground and the push to move to a zero-waste philosophy has created a new perspective. The need to watch budgets and recycle all parts of the plane has become a greater priority. This change is increasing aircraft maintainers need for non-marring aircraft maintenance tools.