Aircraft maintenance is the most important activity that airlines and owners should never underestimate. This maintenance does not stop at the engine, it also includes fasteners, adhesives, and sealants. Aerospace fasteners, adhesives and sealants are vital components to make sure an aircraft can safely fly. The advancement of fasteners, adhesives, and sealants also creates an advancement in products to efficiently replace old fastener, adhesive, and sealants. At Performance Plastics, we have seen the need to improve the tools maintainers use for aircraft maintenance, which is why we created our EnduroSharp® product line.

Aircraft maintenance is the most important activity that airlines and owners should never underestimate. This maintenance does not stop at the engine, it also includes fasteners, adhesives, and sealants. Aerospace fasteners, adhesives and sealants are vital components to make sure an aircraft can safely fly. The advancement of fasteners, adhesives, and sealants also creates an advancement in products to efficiently replace old fastener, adhesive, and sealants. At Performance Plastics, we have seen the need to improve the tools maintainers use for aircraft maintenance, which is why we created our EnduroSharp® product line.

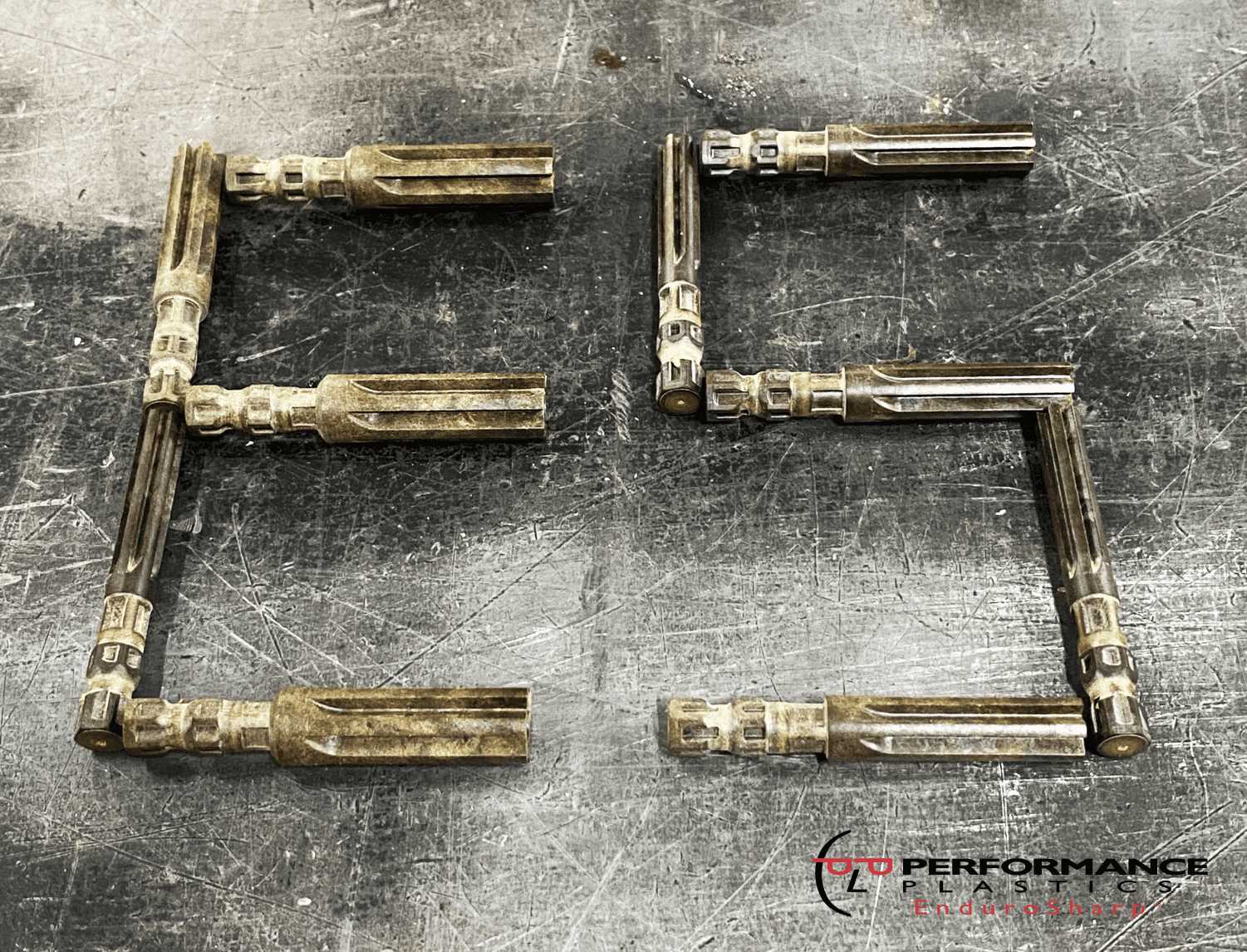

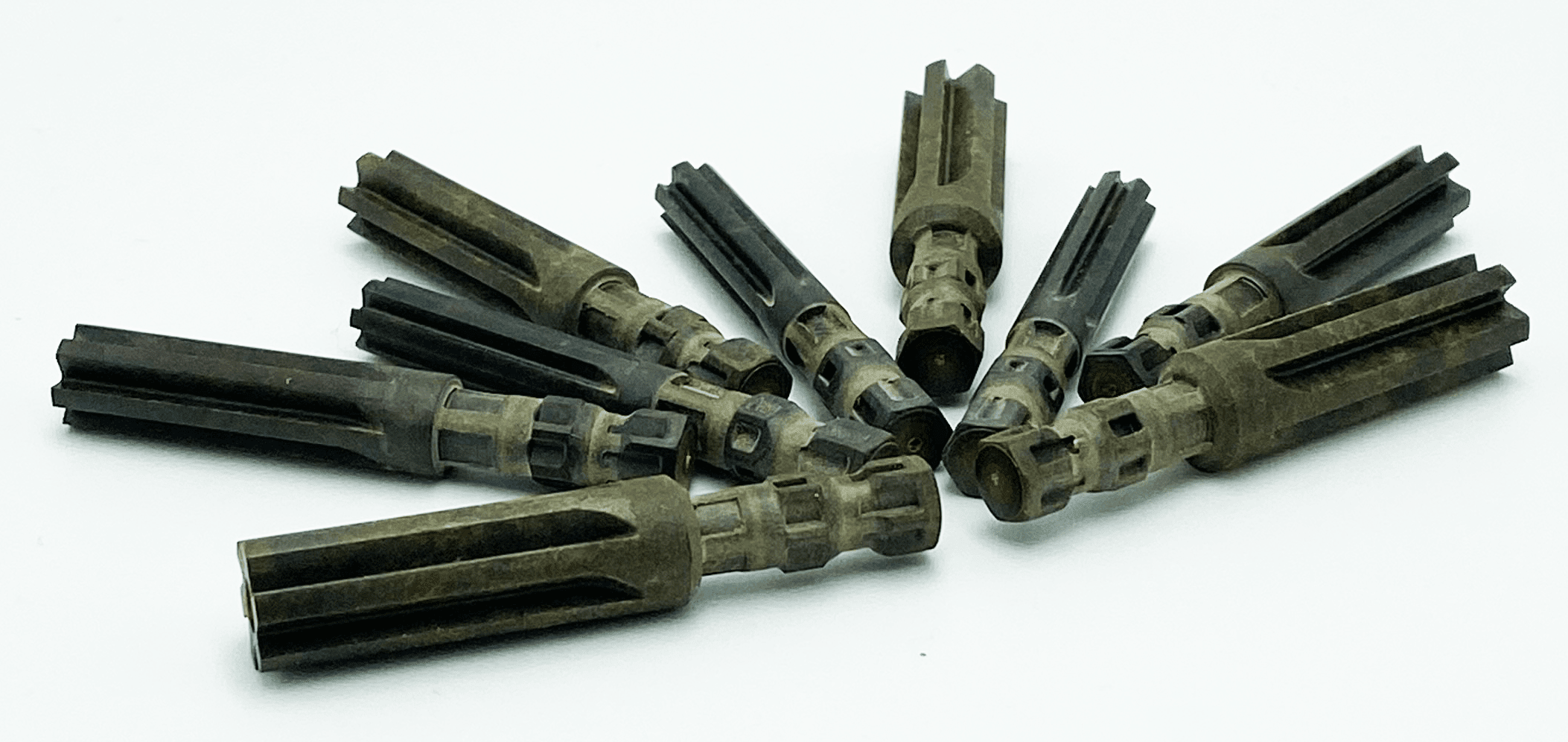

The EnduroSharp® product line has changed the way aerospace maintenance professionals remove sealants and adhesives from substrates and fasteners. Instead of using ineffective metal scrapers and blades, we have created a line of non-marring aircraft maintenance tools. It is our goal to make these tools as efficient as possible, which is why we are constantly wanting feedback from maintainers on all our tools. Most recently we have been working on feedback we have received from our EnduroSharp® Torlon® Adhesive Reamer tools. Maintainers thought the tool worked great, but great can always be better.

The EnduroSharp® Torlon® Adhesive Reamer tools were created to fit into a drill we had in our lab here at Performance Plastics. What we did not know is that the end of our Reamer tool did not correctly lock into other drills used by maintainers. Therefore, we corrected the issue and  redesigned the end of our Reamers to make sure that they fit every drill an aircraft maintainer could possibly use.

redesigned the end of our Reamers to make sure that they fit every drill an aircraft maintainer could possibly use.

At Performance Plastics, we take pride in our ability to solve problems, even when it is our own problem. We know how important it is to use tools that allow you to efficiently and effectively do your job. We take all feedback seriously and want to make our products the best they can be for every person using them.

For more information on our EnduroSharp® product line contact Rich Reed, Vice President of Sales and Marketing, at (513) 321-8404 or [email protected]

The quality behind your product as a manufacturer is the key to long-term success. At Performance Plastics, we hold the quality of our products to the highest standards. We know that quality is critical to satisfying our customers and retaining their loyalty. For this reason, we go above and beyond to make sure our customers products are no less than perfect.

The quality behind your product as a manufacturer is the key to long-term success. At Performance Plastics, we hold the quality of our products to the highest standards. We know that quality is critical to satisfying our customers and retaining their loyalty. For this reason, we go above and beyond to make sure our customers products are no less than perfect. carbon (TOC). The standard also covers surface roughness, particle contribution, metallic contamination, and reliability testing.

carbon (TOC). The standard also covers surface roughness, particle contribution, metallic contamination, and reliability testing.