Nutplates are commonly used on aircraft to allow installation and removal of components and panels for maintenance and repair. The use of bonded nutplates over riveted ones reduces manufacturing complexity and leads to weight savings.

Preparation of these bond surfaces is often accomplished through a manual abrasion process or by using chemical solvent wipes. These methods are difficult to control and can lead to variation in the performance of bonded nutplates. Successful installation of bonded nutplates requires the generation of a highly clean and active bonding surface.

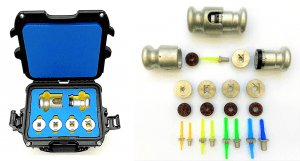

That’s why Performance Plastics in conjunction with the University of Dayton Research Institute developed the EnduroSharp® Nutplate Abrasion Tool “NAT”. The NAT consists of six components: 1 each upper handle (top), 1 each lower handle (base) and 4 each nutplate base inserts.

An alternative to traditional abrasion methods, the “NAT” was specifically designed to allow maintainers to quickly abrade the bond surface of CR series nutplates. The tools radially abrade the bond surface of the nutplate, ensuring that 100% of the bond surface is abraded uniformly in a manner of minutes.

This new technology eliminates interfacial bond failures while increasing pushoff strength and torque-out strength when compared with manual abrasion. Furthermore, the device has been shown to reduce preparation time, decrease variability and lower the instances of nutplate failures both in manufacturing and in the aircraft service environment.

The NAT is available with or without a convenient carrying case. For more information on the Nutplate Abrasive Tool or any other Performance Plastics product, please contact Rich Reed, Vice President of Sales & Marketing for Performance Plastics at [email protected] or call 440-785-7122.

Adhering to a preventive maintenance plan is the number one recommendation of most experts. The current business atmosphere has idled many military, commercial and business aviation programs. Travel restrictions have caused a huge decline in flying, with many planes put in extended storage. However, best practices dictate that preventive maintenance should not be postponed, even during a pandemic.

Adhering to a preventive maintenance plan is the number one recommendation of most experts. The current business atmosphere has idled many military, commercial and business aviation programs. Travel restrictions have caused a huge decline in flying, with many planes put in extended storage. However, best practices dictate that preventive maintenance should not be postponed, even during a pandemic.