EnduroSharp® has changed the way aerospace maintenance professionals remove sealants and adhesives from substrates and fasteners.

EnduroSharp® tools are made from Torlon®, a high strength polymer, creating non-metallic tools that will not damage composite structures during use.

The new, ABNIR “Fly Away” Compact Surface Prep Kit features a selection of commonly used tools with an improved design. Featuring a smaller, compact case, it is easier to store and is an efficient tool kit for aircraft maintenance. The tools are ideal to remove adhesives, sealants and coatings from aircraft structures.

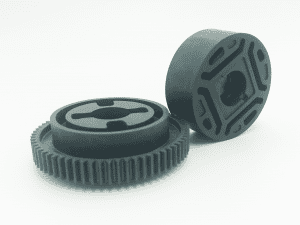

The patented EnduroSharp® lineup consists of a variety of scraper blades, gap blades, reamers, cutter, bits, and discs for removal of substances on aircraft, windmill blades, boat/marine and automotive.

Performance Plastics is a custom precision injection molder of high performance, tight tolerance thermoplastic components. We specialize in geometrically complex precision parts that consist of chemically inert materials. Our expertise led to the development of our patented EnduroSharp® line of Aircraft Maintenance Tools.

For more information on the Enhanced EnduroSharp® Pocket Handle, or any of our EnduroSharp® product line, please contact Rich Reed at [email protected] or our website at www.performanceplastics.com.

PPL has an extensive knowledge of how to create plastic parts equivalent to metal. A high-performance plastic, such as Polyetheretherketone (PEEK), is ideal for parts that demand the high strength of metal, while also being lightweight and resistant to corrosion.

PPL has an extensive knowledge of how to create plastic parts equivalent to metal. A high-performance plastic, such as Polyetheretherketone (PEEK), is ideal for parts that demand the high strength of metal, while also being lightweight and resistant to corrosion. EnduroSharp® has changed the way maintenance professionals remove sealants and adhesives from composite substrates and fasteners. EnduroSharp® tools are made from Torlon®, a high strength, high performance plastic polymer which provides all the benefits of a sharp tool without the risk associated with caustic devices.

EnduroSharp® has changed the way maintenance professionals remove sealants and adhesives from composite substrates and fasteners. EnduroSharp® tools are made from Torlon®, a high strength, high performance plastic polymer which provides all the benefits of a sharp tool without the risk associated with caustic devices.