Ultem Polyetherimide is a material widely used in the medical industry. It is a highly sought-after thermoplastic for its weight saving characteristics and for its use in reusable autoclave sterilization components. Thermoplastic resins become more pliable at warmer temperatures which combined with strength characteristics, thinner walls and larger inner diameters make it a great option for medical tubing such as medical devices.

Thermoplastic polyurethanes dominate the catheter market and are used in some diagnostic and guiding designs. Extruded thermoplastic or thermoset materials are often used in cardiology or interventional radiology. Polyamides and polyamide block copolymers dominate the percutaneous transluminal coronary angioplasty catheter market. They are the polymer of choice for balloon catheters and for stent delivery catheters.

Thermoplastic urethanes and polyether block amides are perhaps the most used thermoplastic elastomers in applications such as catheter tubing, balloons, wound dressings, surgical drapes, storage bags, strain reliefs and numerous other medical device applications.

Ultem is now widely used in:

- Structural Medical Components

- In Vitro Diagnostics

- Medical Respiratory Devices

- Infusion Pumps

- Radiation Therapy Systems

Ultem has exceptional dimensional stability and machinability which makes it suitable for intricate medical devices. It can be molded with different materials like glass fibers, minerals, carbon fibers, etc. to enhance the mechanical strength of the products.

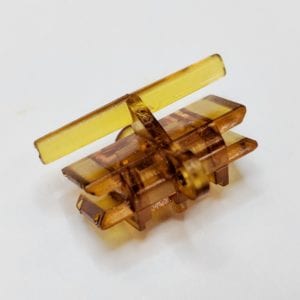

At Performance Plastics, we are experts in injection molding, specializing in high performance plastics. Ultem® is an amorphous material, which can cause complications during the injection molding process. A specific set of conditions, equipment, and processing procedures must be followed to effectively injection mold Ultem®. Our proprietary tool design software, processes and equipment enable us to injection mold components having complex geometries made from challenging ultra, high-performance thermoplastic materials, and reinforced compounds.

Ultem® is one of the many high-performance polymers in which Performance Plastics specializes. For more information on Performance Plastic’s capabilities, please contact Rich Reed, Vice President of Sales and Marketing at 513.321.8404 or email at [email protected]