EnduroSharp® has changed the way aerospace maintenance professionals remove sealants and adhesives from substrates and fasteners.

Adhesively bonded surfaces are increasingly being utilized in the manufacture of aerospace structures, with extensive use in securing removable maintenance access panels.

Traditionally, aerospace maintenance professionals removed adhesives by using unreliable items such as scrapers, files, or grinders. This proved very inefficient because the removal was often uneven leading to failure.

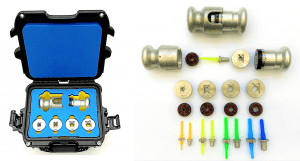

The EnduroSharp® C-130 Prop Hub Adhesive Material Removal Kit comes complete with case with custom foam inserts that contains:

- 2 each pneumatic tools,

- 1 each Class I, Division 2 flashlight,

- 1 each contoured sharpening fixture (requires 120 – 180 grit abrasive paper, sold separately)

- 4 each EnduroSharp® Torlon® Scraper Blades (2 each left hand and 2 each right hand).

Performance Plastics is a injection molder of high performance, precision, tight tolerance thermoplastic resins. We specialize in geometrically complex precision parts that consist of chemically inert materials. Our expertise led to the development of our patented EnduroSharp® line of Aircraft Maintenance Tools.

For more information on the EnduroSharp® C-130 Prop Hub Adhesive Remove Kit or any of our EnduroSharp® product line, please contact Rich Reed at [email protected] or visit our website at www.performanceplastics.com

EnduroSharp® has changed the way aerospace maintenance professionals remove sealants and adhesives from substrates and fasteners.

EnduroSharp® has changed the way aerospace maintenance professionals remove sealants and adhesives from substrates and fasteners. The ability to mold unique and complex parts is what we do at Performance Plastics. Our engineers are constantly pushing the limits of our machines and material in order to produce complex parts. We excel when using high performance plastics for challenging applications.

The ability to mold unique and complex parts is what we do at Performance Plastics. Our engineers are constantly pushing the limits of our machines and material in order to produce complex parts. We excel when using high performance plastics for challenging applications.