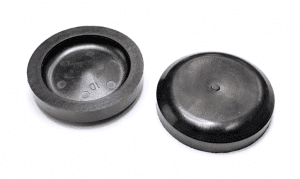

Proprietary impregnated PEEK distributor gear for improved performance and useful life

Metals have been the first choice of design engineers for almost three centuries. Developments in highly engineered thermoplastics materials are challenging that dominance. The aerospace and automotive industries have led the charge in this dramatic changeover, initially driven by the need to reduce weight to gain fuel efficiency. Advanced thermoplastic and thermoset systems, including fiber reinforced compositions, are now finding their way into almost every industry.

PEEK is a mainstay material for a growing variety of applications in many different industries. Its popularity is due to excellent friction and wear characteristics, extended durability under punishing environmental conditions, including high temperatures, abrasion and aggressive chemical environments.

Unfilled PEEK resins emit extremely low levels of smoke and toxic gas when exposed to a flame. Glass and carbon reinforced PEEK resins offer high thermal stability and are among the strongest thermoplastics in the market.

PEEK has a long list of outstanding characteristics making it one of the most popular alternatives to metal:

• High mechanical strength and dimensional stability

• Excellent resistance to harsh chemicals

• High wear resistance

• Low coefficient of friction; high abrasion and cut-through resistance

• Excellent performance at high temperatures

Performance Plastics uses various grades of PEEK resin as metal replacements in applications where few other fluoropolymers would be considered. PEEK is widely used in industries such as: aerospace (commercial and defense), automotive, marine, industrial and energy (fossil fuel and renewable). To discover how PEEK polymer resins can make the transition from metal to thermoplastic easier, please visit our website at https://performanceplastics.com/capabilities/polymer-seals or contact Rich Reed, Vice President of Sales and Marketing, at (513) 321-8404 or [email protected]

EnduroSharp® has changed the way aerospace maintenance professionals remove sealants and adhesives from substrates and fasteners. EnduroSharp® tools are made from Torlon®, a high strength polymer, creating a non-metallic tool that will not damage composite structures during use. The EnduroSharp® lineup consists of a variety of scraper blades, gap blades, reamers, cutters, bits, and discs for removal of adhesives on aircrafts. The product line also includes a variety of kits containing a selection of parts and sizes.

EnduroSharp® has changed the way aerospace maintenance professionals remove sealants and adhesives from substrates and fasteners. EnduroSharp® tools are made from Torlon®, a high strength polymer, creating a non-metallic tool that will not damage composite structures during use. The EnduroSharp® lineup consists of a variety of scraper blades, gap blades, reamers, cutters, bits, and discs for removal of adhesives on aircrafts. The product line also includes a variety of kits containing a selection of parts and sizes. Performance Plastics is a leader in providing innovative production solutions for our customers. We have the opportunity to work on many new projects annually and follow a process guideline called our “Project Development Roadmap”. This process is formatted in a way that everyone involved has a clear view and set expectations.

Performance Plastics is a leader in providing innovative production solutions for our customers. We have the opportunity to work on many new projects annually and follow a process guideline called our “Project Development Roadmap”. This process is formatted in a way that everyone involved has a clear view and set expectations.

EnduroSharp® has changed the way aerospace maintenance professionals remove sealants and adhesives from substrates and fasteners. EnduroSharp® tools are made from Torlon®, a high strength polymer, creating a non-metallic tool that will not damage composite structures during use. The EnduroSharp® lineup consists of a variety of scraper blades, gap blades, reamers, cutters, bits, and discs for removal of adhesives on aircrafts. The product line also includes a variety of kits containing a selection of parts and sizes.

EnduroSharp® has changed the way aerospace maintenance professionals remove sealants and adhesives from substrates and fasteners. EnduroSharp® tools are made from Torlon®, a high strength polymer, creating a non-metallic tool that will not damage composite structures during use. The EnduroSharp® lineup consists of a variety of scraper blades, gap blades, reamers, cutters, bits, and discs for removal of adhesives on aircrafts. The product line also includes a variety of kits containing a selection of parts and sizes. For four decades, Performance Plastics has been delivering the highest quality custom plastic injection molding solutions in the industry for our customers. We take a highly specialized and consultative approach, working closely with our customers to develop the solutions needed to solve the most complicated issues.

For four decades, Performance Plastics has been delivering the highest quality custom plastic injection molding solutions in the industry for our customers. We take a highly specialized and consultative approach, working closely with our customers to develop the solutions needed to solve the most complicated issues.