Engineered Plastic Medical Devices are revolutionizing the healthcare industry. The growth of polymers has transformed the marketplace, with plastic medical devices steadily replacing other materials such as glass, ceramics, and metals, wherever applicable.

Peek (Polyether Ether Ketone) plastics are widely used in the medical device industry due to their excellent mechanical properties, biocompatibility, and resistance to chemicals and high temperatures. Here are some ways Peek plastics are used in medical devices:

- Implants: Peek is commonly used in orthopedic implants, such as spinal fusion cages, joint replacements, and trauma fixation plates. Its mechanical properties closely resemble those of bone, making it an ideal material for load-bearing applications. Peek’s biocompatibility allows it to integrate well with the surrounding tissue.

- Dental Applications: Peek is used in dental applications like dental implants, temporary crowns and bridges, orthodontic brackets, and dental surgical instruments. It provides good strength and stability, and its tooth-colored variants offer aesthetic benefits.

- Surgical Instruments: Peek is utilized in the manufacturing of surgical instruments, including forceps, retractors, and endoscopic components. Its high strength, durability, and resistance to sterilization methods such as autoclaving make it suitable for repeated use.

- Medical Device Housings: Peek is used for the housing and structural components of various medical devices, such as handheld surgical tools, electronic devices, and monitoring equipment. Its mechanical strength, resistance to sterilization, and biocompatibility make it suitable for these applications.

- Ophthalmic Devices: Peek is used in the manufacture of intraocular lenses (IOLs), which are artificial lenses implanted in the eye during cataract surgery. Peek’s optical clarity, biocompatibility, and resistance to degradation within the eye make it a preferred material for IOLs.

Peek plastics offer several advantages for medical devices, including their radiolucency (compatibility with X-rays), high strength-to-weight ratio, chemical resistance, and biocompatibility. These properties make Peek a versatile and reliable material choice in various medical applications.

For more information on PEEK and its use in medical applications, please contact Rich Reed, Vice President of Sales & Marketing at [email protected], or visit our website at www.performanceplastics.com.

Micro injection molding is a specialized form of injection molding that is used to produce small, intricate parts with high precision and accuracy, It has gained significant attention in various industries, including medical devices, electronics, automotive, and aerospace/defense. In recent years, several innovations have emerged in micro injection molding, improving its capabilities, and expanding its applications.

Micro injection molding is a specialized form of injection molding that is used to produce small, intricate parts with high precision and accuracy, It has gained significant attention in various industries, including medical devices, electronics, automotive, and aerospace/defense. In recent years, several innovations have emerged in micro injection molding, improving its capabilities, and expanding its applications.

Celcon® plastic scraper blades are currently approved by several MROs and are made of semi-crystalline thermoplastics that offer high tensile strength, stiffness, and toughness and may retain a sharp edge. They are resistant to hot water and some solvents and are useful for sealant application, removal, and paint removal. They are not, however, useful with newer aviation adhesives, or high-heat applications as they melt easily. Celcon® dust may cause irritation in the upper respiratory tract when used at normal processing temperatures.

Celcon® plastic scraper blades are currently approved by several MROs and are made of semi-crystalline thermoplastics that offer high tensile strength, stiffness, and toughness and may retain a sharp edge. They are resistant to hot water and some solvents and are useful for sealant application, removal, and paint removal. They are not, however, useful with newer aviation adhesives, or high-heat applications as they melt easily. Celcon® dust may cause irritation in the upper respiratory tract when used at normal processing temperatures.

Torlon® scraper blades hold a superior edge, remove unwanted materials, and protect the underlying substrates. Torlon® is a non-marring, high-strength, high-temperature polymer and is cured to produce a thermoset polymer. As a thermoset, it is resharpenable, lightweight, chemically resistant, and safe for people under normal conditions.

Torlon® scraper blades hold a superior edge, remove unwanted materials, and protect the underlying substrates. Torlon® is a non-marring, high-strength, high-temperature polymer and is cured to produce a thermoset polymer. As a thermoset, it is resharpenable, lightweight, chemically resistant, and safe for people under normal conditions. Strong, lightweight plastics enable us to live better while contributing to sustainability in many ways—all which stem from plastics’ ability to help us do more with less.

Strong, lightweight plastics enable us to live better while contributing to sustainability in many ways—all which stem from plastics’ ability to help us do more with less.

als, and poppets are key components of industrial applications used to seal joints, limit vibration, and prevent leaks. They serve critical functions, so it is essential to choose the correct material for the application. Performance Plastics has a thorough understanding of high-performance thermoplastics including PEEK, PFA, FEP, Torlon, and Ultem to create reliable, better sealing, longer wearing, and more cost-efficient components.

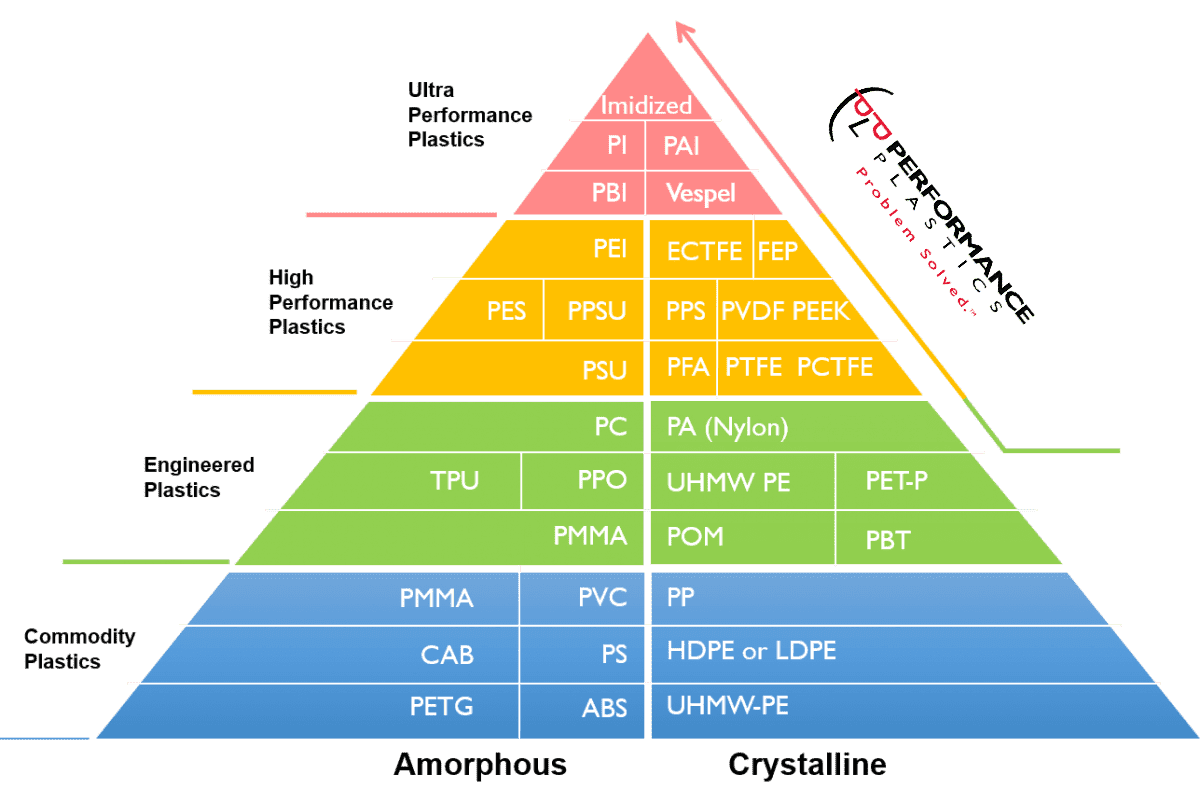

als, and poppets are key components of industrial applications used to seal joints, limit vibration, and prevent leaks. They serve critical functions, so it is essential to choose the correct material for the application. Performance Plastics has a thorough understanding of high-performance thermoplastics including PEEK, PFA, FEP, Torlon, and Ultem to create reliable, better sealing, longer wearing, and more cost-efficient components. Plastics can be considered high-performance for a variety of reasons. The specific application and the performance criteria are the most important. Here are some characteristics that can contribute to a resin being classified as a high-performance plastic.

Plastics can be considered high-performance for a variety of reasons. The specific application and the performance criteria are the most important. Here are some characteristics that can contribute to a resin being classified as a high-performance plastic.