Walking through our factory it is readily apparent we take quality seriously and invest substantial resources in state-of-the-art quality inspection tools. Starting from the CEO on down, Performance Plastics hammers home the importance of maintaining the utmost quality standards. Our employees have embraced this quality culture and see the economic commitment we make in training and tools.

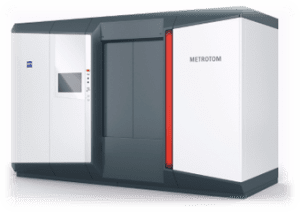

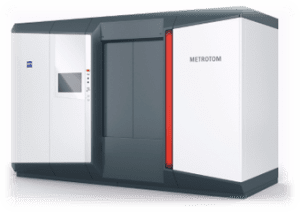

We injection mold a variety of high volume medical instrument, diagnostic lab, aerospace & defense and industrial thermoplastic components where it is an absolute necessity to ship 100% conforming parts. In many cases, human inspection with its inherent error rates are not a practical alternative. As such, we have made substantial investments in multiple robotic handling and automated vision inspection systems necessary to meet our customers rigorous requirements. For example, we designed and invested in an automated inspection cell which performs 100% inspection on over 60 microscopic features per part on over 2 million consumable diagnostic lab components manufactured per month. We also have invested substantial capital in automated leak testing which we perform to .02 standard liters per minute on critical use valve seals and certain defense components. Finally, industrial CT scanning gives our customers access to the inner workings of a part without having to destroy the original, allowing for a thorough analysis of object dimensions, porosity, wall thickness, assembly defects, comprehensive comparisons, and reverse engineering.

Please contact us to set up your factory tour.

Certifications:

Performance Plastics achieved certification to ISO 9001:2000 in March of 2003 and has maintained our certificate in good standing since that time. In March of 2015, with updates in place, we were audited and re-certified to ISO 9001:2015.

Additionally, Performance Plastics is ITAR registered.