This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

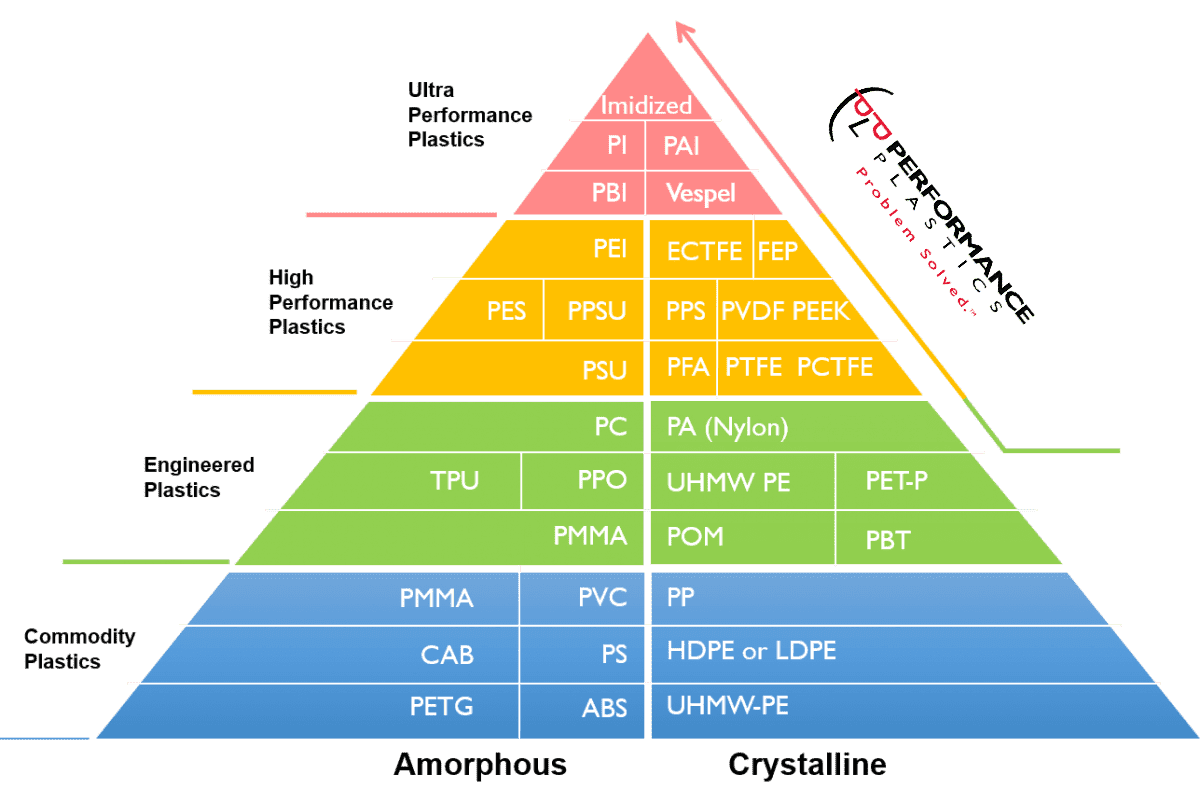

Highly Engineered Thermoplastic Materials

We have an extensive history of injection molding filled and unfilled ultra and high performance thermoplastics resins (PEEK, PFA, FEP, Torlon®, Ultem®, EXTEM®, etc.), and partnering with world class polymer scientists and industry leading material suppliers to develop unique custom resin formulations to address our customers needs. This page highlights a few of the materials we commonly injection mold.

FEP (Fluorinated Ethylene Propylene)

FEP is a highly inert material compatible with most organic compounds. It is virtually impervious to chemical, enzyme and microbiological attack and stiffer than PTFE. The non-stick properties of this polymers can also be useful to reduce liquid, gel and powder adhesion.

While significantly less expensive than PFA, FEP is very difficult to mold due to its low viscosity. However, Performance Plastics has developed proprietary tooling and processes enabling the injection molding of small, thin-walled, complex FEP parts.

- More transparent than PTFE (not injection moldable)

- Better gas and vapor permeability properties than PTFE

- Maximum working temperature 400°F

PFA (Perfluoroalkoxy)

PFA is an injection moldable, highly inert material similar to FEP , however it is significantly more expensive. Fluoropolymers in general, have good dielectric properties and are resistant to atmospheric degradation.

PFA is significantly easier to mold than FEP, but the ease must be related to the expense.

- Higher continuous service temperature than FEP

- Maximum working temperature 500°F

- Difference in molecular structure gives PFA improved flow, creep resistance and thermal stability.

PAI (Polyamidimide) Torlon®

An early member of the high performance plastics family, PAI is a high strength, high temperature (500°F max) polymer that is injection molded and oven “cured” to produce a thermoset polymer with excellent bearing properties. PAI has the highest tensile strength of all non-filled, injection moldable materials. It should be noted that water absorption can be a concern and a 17 day post cure process is required. Use of this material requires special certification which we have obtained.

- Low friction/wear

- High compressive strength

- Outstanding performance at elevated temperatures.

PEEK (Polyetheretherketone)

Well suited for high temperature and wear applications, PEEK mechanical properties and a flexural modulus are among the highest of all plastic resins. Outstanding chemical resistance, even at elevated temperatures, resists most common organic compounds and is not attacked by water or pressurized steam. Because of its superior properties, PEEK is actively used in metal replacement applications.

- Excellent friction and wear characteristics

- Extremely high tensile strength

- FDA approved

- Meets UL94 V-0 requirements

PPS (polyphenylene sulfide) Ryton®

PPS is an engineered thermoplastic, that offers an exceptional balance of properties. PPS has a high-temperature resistance, chemical resistance, flowability, and dimensional stability. Making PPS a useful material in electronics, automotive, aerospace, and chemical industries.

- • Excellent hydrolytic stability

• Inherently self-extinguishing (UL 94 V0)

• Precision molding to tight tolerances with high reproducibility

PEI (Polyetherimide) Ultem®

An amorphous material with exceptional strength and rigidity under long term heat exposure, PEI has excellent impact strength, flame resistance and generates very low levels of smoke when burned. PEI also has excellent hydrolytic stability and is well suited for repeated steam sterilization. These properties are very useful for applications requiring tight tolerances and low warp.

- Excellent chemical resistance

- Good high temperature characteristics

- Precise tolerance control

Celazole® PBI (polybenzimidazole)

Celazole® PBI (polybenzimidazole) is a unique and highly stable linear heterocyclic polymer. PBI is an engineered thermoplastic that has exceptional characteristics such as high compressive strength, high modulus, low creep, and solubility in few solvents.

- Highest compressive strength of any unfilled resin

- Excellent tensile and flexural strength

- Good fatigue properties; low creep

TPI (Polyimide) EXTEM®

Extem combines polyetheretherketone (PEEK) into its polyimide resin technology base. Combining the best features of both materials allows for lower-weight, high-temperature continuous use applications when replacing metals, ceramics and thermosets for optimized performance in harsh environment applications.

- Extremely high continuous heat

- Excellent friction and wear

- Flame-retardant

Nylon (Polyamide, Zytel®, Nylon 66)

Outstanding chemical resistance, even at elevated temperatures, resists most common organic compounds and is not attacked by water or pressurized steam. Glass and carbon fillers can increase strength and thermal stability. Because of its superior properties, Nylon is actively used in metal replacement applications.

- Excellent friction and wear characteristics

- Extremely high tensile strength

- Maximum working temperature 500°F

Daikin® Neoflon ™

Daikin® Polyflon ™

Daikin PTFE (polytetrafluoroethylene) products offer a broad range of characteristics including chemical stability, electrical properties, heat resistance, non-sticking and low-friction properties as well as dielectric characteristics. .

- Lowest coefficient of friction

- Highest heat resistance

- Chemical resistance

- Electrical properties