Introducing our Improved EnduroSharp® Nutplate Abrasion Tool

The “NAT”

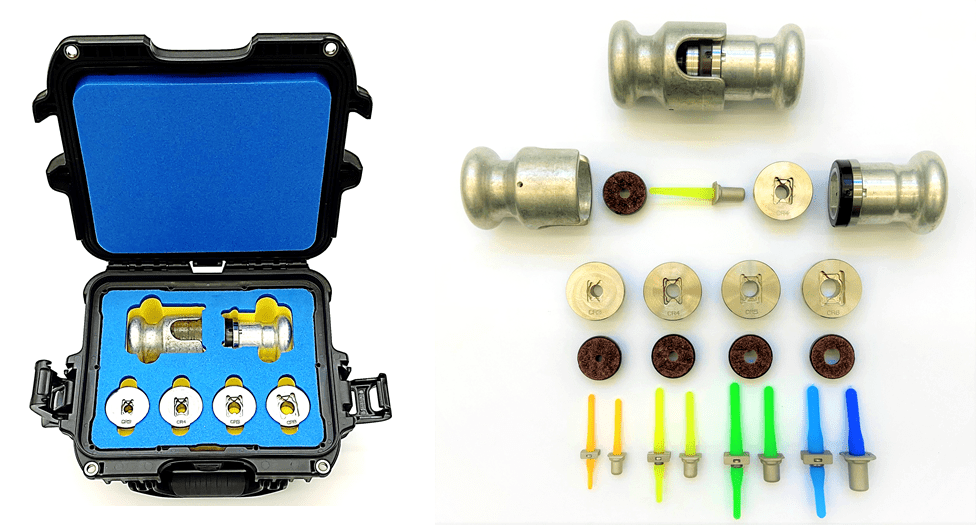

Part Number: ESNAT-1

Introducing the EnduroSharp® Nutplate Abrasion Tool “The NAT”. The NAT consists of six components 1 each upper handle (top), 1 each lower handle (base) and 4 each nutplate base inserts.

The NAT along with the specially designed abrasive pads (sold separately) allows the maintainer to quickly abrade the bond surface of CR series nutplates. The tools radially abrades the bond surface of the nutplate, ensuring that 100% of bond surface is abraded uniformly in a matter of minutes.

The NAT is available with or without a convenient carrying case. The rugged case comes with a high-density custom foam insert for easy inventory and protection. The product is available individually, or as part of the ABNIR Kit.

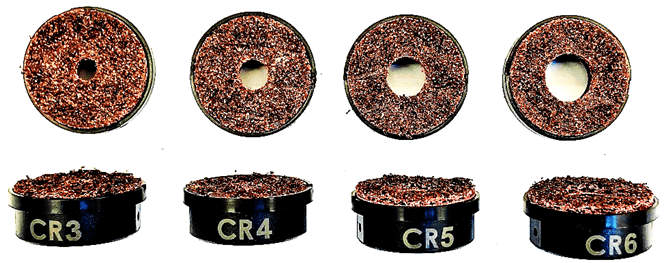

NAT “CR Series” Abrasive Pads

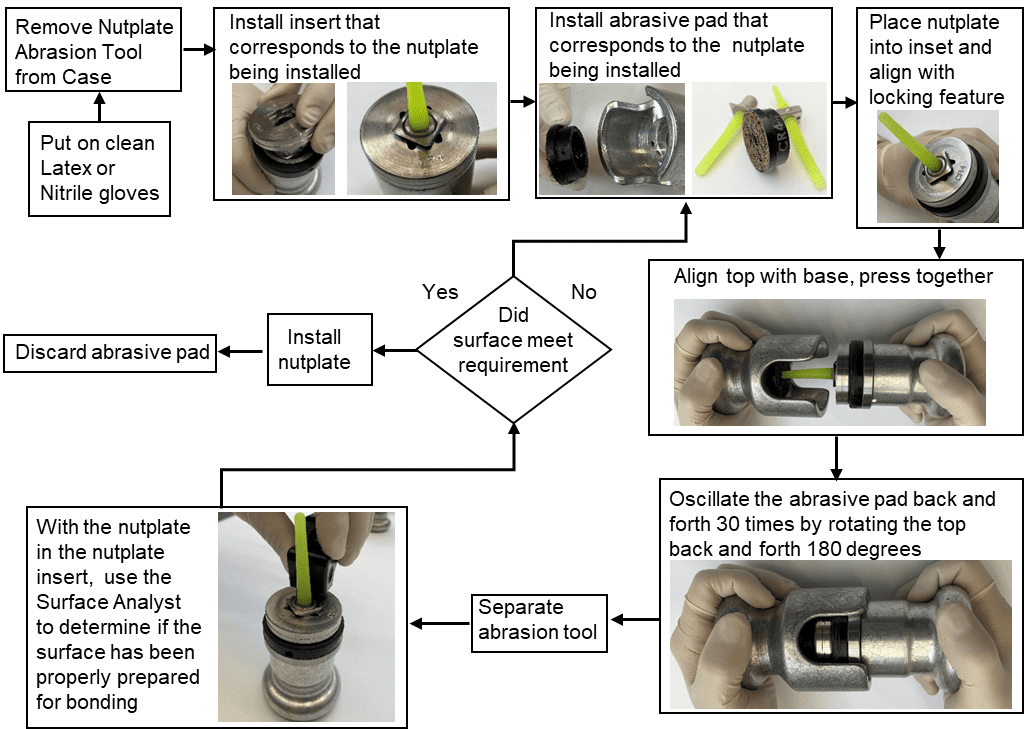

Nutplate Abrasion Tool (NAT) Operational Flow Chart

Nutplate Abrasion Tool (NAT) Operation

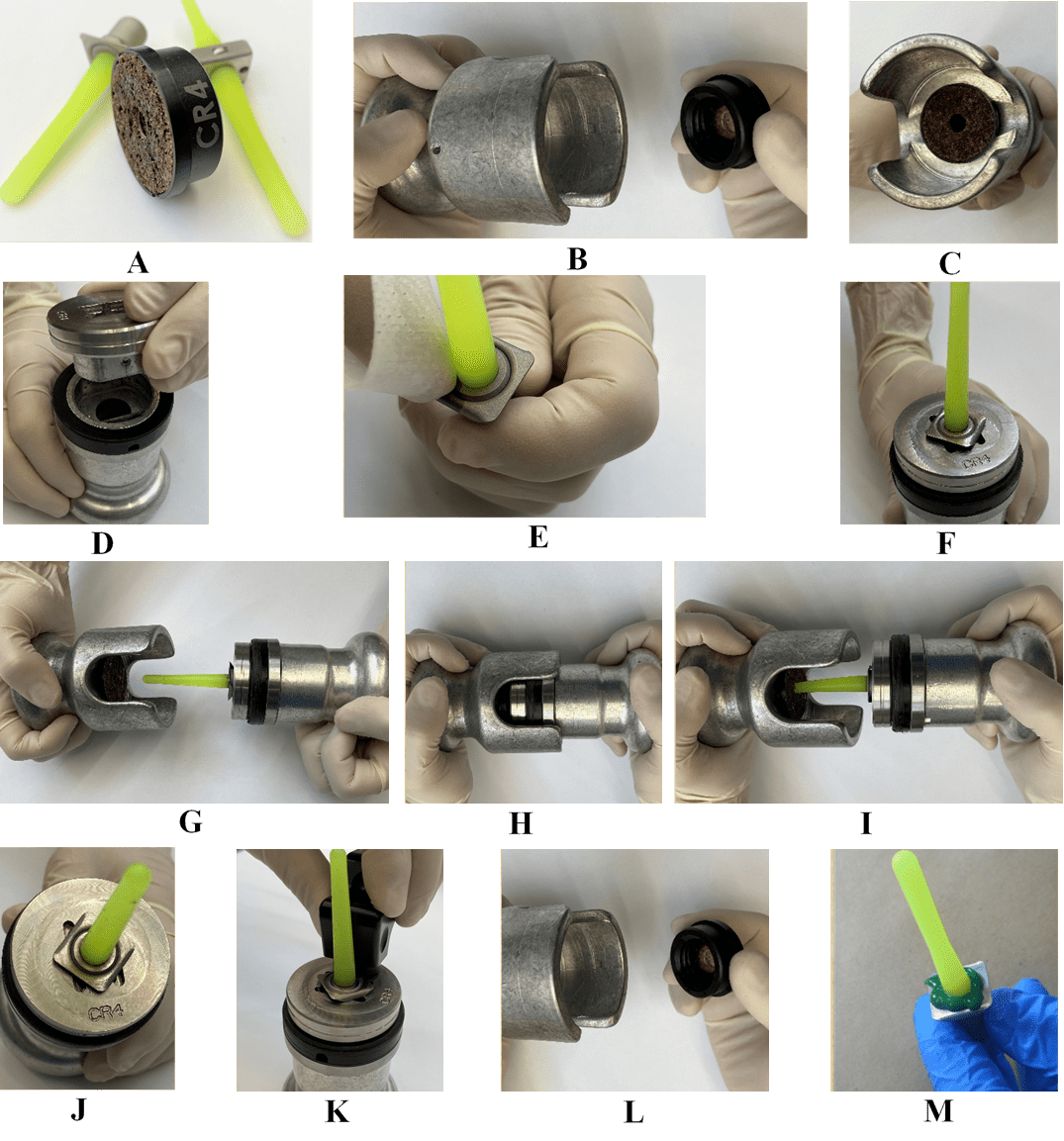

- Select the appropriate unused abrasive pad that matches the nutplate being installed.

- Align flats on an unused abrasive pad with the flats and detent pins in the NAT upper handle (top) and snap into place.

- Ensure abrasive pad is fully seated in the top portion of the NAT.

- Align and snap the NAT nutplate insert that matches the size of the nutplate being installed into the NAT lower handle (base).

- Solvent wipe the nutplate being installed with the appropriate solvent and AMS3819 wipes.

- base, press together, feeding the nutplate fixture through the hole in the abrasive pad and seat the nutplate bond surface to be abraded against the abrasive pad.

- Oscillate the abrasive pad back and forth 15 times by rotating the NAT top and base back in opposite directions

- Separate the NAT top from the base

- Inspect nutplate bond surface for uniform abrasion (Do not touch, wipe or clean the abraded surface). Reseat nutplate in the NAT nutplate insert and measure the abraded nutplate surface with the Surface Analyst (SA reading less than 50 is required). Re-abrade if necessary.

- Discard the used abrasive pad.

- Apply appropriate adhesive to nutplate bond surface and install in structure per Technical Data or manufactures directions.