Industrial CT Scanning can help during multiple manufacturing stages

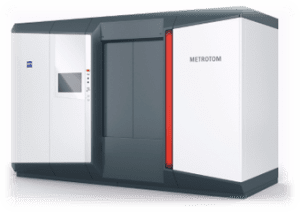

CINCINNATI, Ohio, April 30, 2019 ― Performance Plastics is pleased to announce a new service that helps round out its offering: industrial computed tomography (CT) scanning.

Industrial CT scanning gives customers access to the inner workings of a part without having to destroy the original. The scanner rotates the part 360 degrees and uses X-rays to create a precise 3D model. This allows for a thorough analysis of object dimensions, porosity, wall thickness, assembly defects, comprehensive comparisons, and reverse engineering.

Industrial CT scanning gives customers access to the inner workings of a part without having to destroy the original. The scanner rotates the part 360 degrees and uses X-rays to create a precise 3D model. This allows for a thorough analysis of object dimensions, porosity, wall thickness, assembly defects, comprehensive comparisons, and reverse engineering.

The CT scan can then be compared to the CAD model and to other parts. Plus, it can easily analyze surface variations and provide cross sections to reveal hidden features.

Performance Plastics offers a variety of CT scan-related services:

- Part-to-CAD comparisons create a precise overlay of the scanned part to the original 3D part model database

- Part-to-part comparisons provide an overlay of two scanned parts to reveal dimensional deviation

- Void and inclusion analysis provides material and defect analysis showing void or inclusion size and locations

- Wall thickness analysis measures slight changes in the wall stock of complex parts without destructive testing

- Dimensional analysis provides full article inspections and reporting

- Reverse engineering capabilities that generate a 3D CAD file

“Industrial CT scanning can be necessary during five different manufacturing stages,” said Rich Reed, Vice President of Sales and Marketing. “When you’re in pre-production, it can help with the project design and analysis. During production, you can use CT scanning to evaluate consistency. At the failure investigation stage, it will find defects. The CT scanner can run repeatability tests when you’re doing inspections. And if you need design adjustments or are doing further R&D, it can help with reverse engineering.”

As for what Performance Plastics can handle when CT scanning:

- Maximum part size is 300mm diameter x 350 mm tall

- Scan time is typically less than one hour

- Accuracy (using Calypso) of 9+L/50 microns

- X-ray-based measurement system is non-contact

- Parts do not require potting

About Performance Plastics

We are problem solvers. We design and manufacture injection molded parts made with ultra-high-performance plastics such as Torlon®, PEEK, Ultem® and fluoropolymers. (FEP, PFA, PVDF). We specialize in molding parts with complex geometries and very tight tolerances for critical applications such as aerospace/defense, medical, and energy. We achieve this by combining a unique product design approach with proprietary process technology and state-of-the art quality control that provides our customers the “lowest cost solution.” Our engineers deliver results where others say, “it can’t be done.”