Aircraft Maintenance Professionals are always looking for better and more efficient ways to complete their tasks. Sometimes, in an effort to complete their tasks faster, they use items that were not designed for use in removal and damage to the underlying surfaces.

While there are currently many scraper blades on the market that are designed for adhesive removal, , not all materials are created equal. Most of the blades currently on the market are made of three materials: ABS, Phenolic, and Torlon.

ABS

Acrylonitrile Butadiene Styrene is a very tough, very durable thermoplastic used in a wide variety of applications. ABS is a common choice among other plastic production materials because of its durability, structural stability, and good corrosion, impact, chemical, and wear resistance.

ABS plastic is made when acrylonitrile and polystyrene monomers are polymerized with butadiene rubber to create acrylonitrile butadiene styrene (ABS). This blending is typically accomplished using an emulsification process, wherein materials that would otherwise not mix are formulated into a cohesive single product (think milk, where fats, oil, and water do not separate out of solution but exist as a homogenous mixture)

Phenolic

Phenolic is a laminated plastic used in a variety of custom plastic components due to its high strength, resistance to solvents, dielectric strength, and many other features.

Phenolics are manufactured by impregnating layers of material with a phenolic resin, and then applying heat and pressure, which transforms these layers into a solid mass. The result is a thermoset that is dense, dimensionally stable, structurally strong, has low creep, and is an excellent insulator.

Torlon

Torlon® is a high-strength, high-performance, melt-processable plastic material. It’s ability to perform under severe stress combined with its resistance to elevated temperatures makes it ideal for various applications across many industries. Torlon (PAI) is recognized as being the highest-performing plastic that is melt-processable.

Polyamide-imides (PAIs) are thermoplastic amorphous polymers prepared by the condensation of an aromatic diamine, such as methylene diamine, and an anhydride, such as trimellitic acid chloride. PAIs have good mechanical, thermal, and chemical resistance, high strength, melt processability, and high heat capacity.

So, ABS is blended thermoplastic, Phenolic is impregnated plastic, and Torlon is a heat-treated, condensed thermoset. Condensed thermoset materials are stronger, more resilient, and exhibit consistent performance without the risk of damaging the surfaces.

EnduroSharp® Torlon® aircraft maintenance tools were specifically designed by Performance Plastics, the Airforce Research Laboratory (ARL), and the University of Dayton Research Institute at Wright Patterson Air Force Base to safely and efficiently remove adhesives, sealants, and coatings while maintaining an effective edge and not damaging the underlying substrates.

For more information on Torlon® and/or EnduroSharp Torlon® Aircraft Maintenance Tools, please contact Aileen Crass, Product Marketing Manager at [email protected], or visit our website at www.performanceplastics.com/endurosharp.

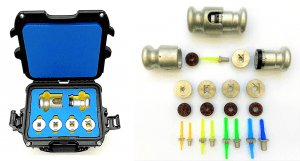

Performance Plastics is pleased to announce two additions to its EnduroSharp® line of aircraft maintenance tools: the EnduroSharp® Torlon® Sealant Remover (TSR) and three new EnduroSharp® Adhesive Reamers (TAR).

Performance Plastics is pleased to announce two additions to its EnduroSharp® line of aircraft maintenance tools: the EnduroSharp® Torlon® Sealant Remover (TSR) and three new EnduroSharp® Adhesive Reamers (TAR).

Introducing the EnduroSharp® TSR Cutter, specifically designed for larger aircraft maintenance applications. Made from resharpenable Torlon®, the SR Cutter is the newest addition to the EnduroSharp® line of tools.

Introducing the EnduroSharp® TSR Cutter, specifically designed for larger aircraft maintenance applications. Made from resharpenable Torlon®, the SR Cutter is the newest addition to the EnduroSharp® line of tools.

Celcon® plastic scraper blades are currently approved by several MROs and are made of semi-crystalline thermoplastics that offer high tensile strength, stiffness, and toughness and may retain a sharp edge. They are resistant to hot water and some solvents and are useful for sealant application, removal, and paint removal. They are not, however, useful with newer aviation adhesives, or high-heat applications as they melt easily. Celcon® dust may cause irritation in the upper respiratory tract when used at normal processing temperatures.

Celcon® plastic scraper blades are currently approved by several MROs and are made of semi-crystalline thermoplastics that offer high tensile strength, stiffness, and toughness and may retain a sharp edge. They are resistant to hot water and some solvents and are useful for sealant application, removal, and paint removal. They are not, however, useful with newer aviation adhesives, or high-heat applications as they melt easily. Celcon® dust may cause irritation in the upper respiratory tract when used at normal processing temperatures.

Torlon® scraper blades hold a superior edge, remove unwanted materials, and protect the underlying substrates. Torlon® is a non-marring, high-strength, high-temperature polymer and is cured to produce a thermoset polymer. As a thermoset, it is resharpenable, lightweight, chemically resistant, and safe for people under normal conditions.

Torlon® scraper blades hold a superior edge, remove unwanted materials, and protect the underlying substrates. Torlon® is a non-marring, high-strength, high-temperature polymer and is cured to produce a thermoset polymer. As a thermoset, it is resharpenable, lightweight, chemically resistant, and safe for people under normal conditions.