As you’re designing and manufacturing your next project, wouldn’t it be ideal if you could analyze all the existing parts, compare them to the original drawings, and get results quickly, without damage? At Performance Plastics, we have the ability to do this through industrial computed tomography (CT) scans. This gives us the ability to measure all aspects of your part, without having to damage it.

As you’re designing and manufacturing your next project, wouldn’t it be ideal if you could analyze all the existing parts, compare them to the original drawings, and get results quickly, without damage? At Performance Plastics, we have the ability to do this through industrial computed tomography (CT) scans. This gives us the ability to measure all aspects of your part, without having to damage it.

Performance Plastics specializes in tight tolerance, high-performance polymers such as Peek, Torlon, FEP & PFA, and Ultem. We leverage CT Industrial scanning to replicate parts made of other materials and improve their performance.

Industrial computed tomography (CT) scanning is a non-destructive testing (NDT) method that uses X-ray technology to produce detailed 3D images of the internal structure of objects. This technology is widely used across various industries due to its numerous benefits. Here are some key advantages of industrial CT scanning:

- Non-Destructive Testing (NDT): One of the primary benefits of industrial CT scanning is that it allows for non-destructive testing of objects. This means that the internal structures of components or products can be examined without causing any damage to the tested item. This is particularly important in industries where preserving the integrity of the object is crucial.

- High Resolution and Accuracy: Industrial CT scanners can produce high-resolution images with fine details, allowing for precise analysis of internal structures. This level of accuracy is especially valuable in industries where the quality and precision of components are critical, such as aerospace and automotive.

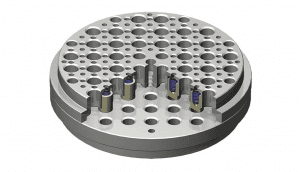

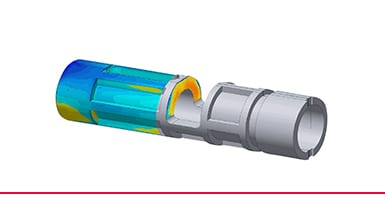

- Visualization of Internal Structures: CT scanning provides a three-dimensional visualization of the internal features of an object. This is particularly useful for inspecting complex geometries, assemblies, and multi-material components, allowing engineers and researchers to examine the internal structures in a comprehensive manner.

- Identification of Defects and Anomalies: Industrial CT scanning is highly effective in identifying defects, voids, cracks, and other anomalies within an object. This can be crucial for quality control and ensuring that products meet industry standards and safety requirements.

- Reduced Inspection Time: Compared to traditional methods of inspection, industrial CT scanning can significantly reduce inspection time. This is especially beneficial for industries where efficiency and rapid inspection are essential.

- Versatility: Industrial CT scanning can be applied to a wide range of materials, including metals, plastics, composites, and more. This versatility makes it a valuable tool across various industries, from manufacturing to medical research.

- Reverse Engineering: CT scanning can be used for reverse engineering applications, where the internal and external geometries of a component are captured digitally. This is useful for replicating or modifying existing components.

- Regulatory Compliance: In industries where compliance with safety and quality standards is essential, industrial CT scanning can help meet regulatory requirements by providing thorough and accurate inspections. In summary, industrial CT scanning offers a non-destructive, highly accurate, and versatile method for inspecting internal structures of objects, making it a valuable tool in various industries for quality control, research, and product development.

At Performance Plastics, we are experts in injection molding, specializing in high-performance plastics such as PEEK, Torlon, FEP & PFA, and Torlon for medical, aerospace, and industrial applications. Our proprietary tool design software, processes, and equipment enable us to injection mold components having complex geometries made from challenging ultra, high-performance thermoplastic materials, and reinforced compounds.

For more information on Performance Plastic’s capabilities, please contact Rich Reed, Vice President of Sales, and Marketing at 513.321.8404 or email at [email protected].

als, and poppets are key components of industrial applications used to seal joints, limit vibration, and prevent leaks. They serve critical functions, so it is essential to choose the correct material for the application. Performance Plastics has a thorough understanding of high-performance thermoplastics including PEEK, PFA, FEP, Torlon, and Ultem to create reliable, better sealing, longer wearing, and more cost-efficient components.

als, and poppets are key components of industrial applications used to seal joints, limit vibration, and prevent leaks. They serve critical functions, so it is essential to choose the correct material for the application. Performance Plastics has a thorough understanding of high-performance thermoplastics including PEEK, PFA, FEP, Torlon, and Ultem to create reliable, better sealing, longer wearing, and more cost-efficient components. As you’re designing and manufacturing your next application, wouldn’t it be ideal if you could analyze all the parts, compare them to the original drawings and get results quickly, without damage? At Performance Plastics, we have the ability to do this through industrial computed tomography (CT) scan. Giving us the ability to measure all aspects of your part, without having to damage it.

As you’re designing and manufacturing your next application, wouldn’t it be ideal if you could analyze all the parts, compare them to the original drawings and get results quickly, without damage? At Performance Plastics, we have the ability to do this through industrial computed tomography (CT) scan. Giving us the ability to measure all aspects of your part, without having to damage it.