Design for Manufacturing (DFM) is a crucial aspect of the plastic injection molding process. It involves optimizing the design of a plastic part to ensure that it can be easily and cost-effectively manufactured using injection molding techniques. Here are some key considerations and guidelines for DFM in plastic injection molding:

Part Geometry and Complexity:

- Keep the part geometry simple and avoid intricate features that could complicate the molding process or require complex tooling.

- Minimize the use of undercuts, sharp corners, and thin walls to prevent molding defects and challenges in ejection.

Draft Angle:

- Incorporate draft angles (tapered surfaces) on vertical walls to facilitate easy ejection of the part from the mold.

- A typical draft angle is around 1-2 degrees per side, but this may vary based on the material and part design.

Wall Thickness:

- Maintain uniform wall thickness throughout the part to ensure proper flow of molten plastic and reduce the risk of sink marks, warping, or voids.

- Avoid sudden transitions between thick and thin sections, as this can lead to molding defects.

Ribs and Bosses:

- Use ribs to reinforce thin sections of the part and add structural integrity.

- Design bosses (protruding features) with appropriate wall thickness and draft angles to ensure good mold filling and easy part ejection.

Corners and Fillets:

- Incorporate rounded corners and generous fillet radii to distribute stress and prevent stress concentrations that could lead to part failure.

Material Selection:

- Choose a suitable plastic material for the intended application, considering factors such as mechanical properties, chemical resistance, temperature stability, and more.

Gating and Venting:

- Position the gate (entry point for molten plastic) in a location that minimizes aesthetic defects and ensures uniform filling.

- Provide adequate venting to allow air and gases to escape during injection, preventing voids and trapped air.

Texture and Surface Finish:

- Consider the desired texture or surface finish early in the design process, as this may impact mold design and material flow.

- Textures can help hide imperfections and improve aesthetics.

Tolerances:

- Specify realistic tolerances that are achievable through the injection molding process.

- Avoid tight tolerances that could increase manufacturing costs and lead to rejects.

Moldability Analysis:

- Conduct mold flow analysis using simulation software to identify potential issues and optimize the part design before production.

- Address potential concerns such as weld lines, air traps, and flow imbalances.

Tooling Considerations:

- Collaborate closely with the tooling manufacturer to ensure the mold design aligns with the part design and material properties.

- Optimize the number and complexity of mold cavities based on production volume requirements.

Assembly and Post-Processing:

- Design parts for easy assembly by incorporating features like snap fits, self-locating tabs, and mating surfaces.

- Minimize the need for secondary operations or post-processing steps.

By following these design principles and collaborating with experienced injection molding professionals like Performance Plastics, you can create plastic parts that are well-suited for efficient and cost-effective manufacturing through the injection molding process.

For more information on Design for Manufacturing and its use, please contact Rich Reed, Vice President of Sales & Marketing at [email protected], or visit our website at www.performanceplastics.c

Strong, lightweight plastics enable us to live better while contributing to sustainability in many ways—all which stem from plastics’ ability to help us do more with less.

Strong, lightweight plastics enable us to live better while contributing to sustainability in many ways—all which stem from plastics’ ability to help us do more with less.

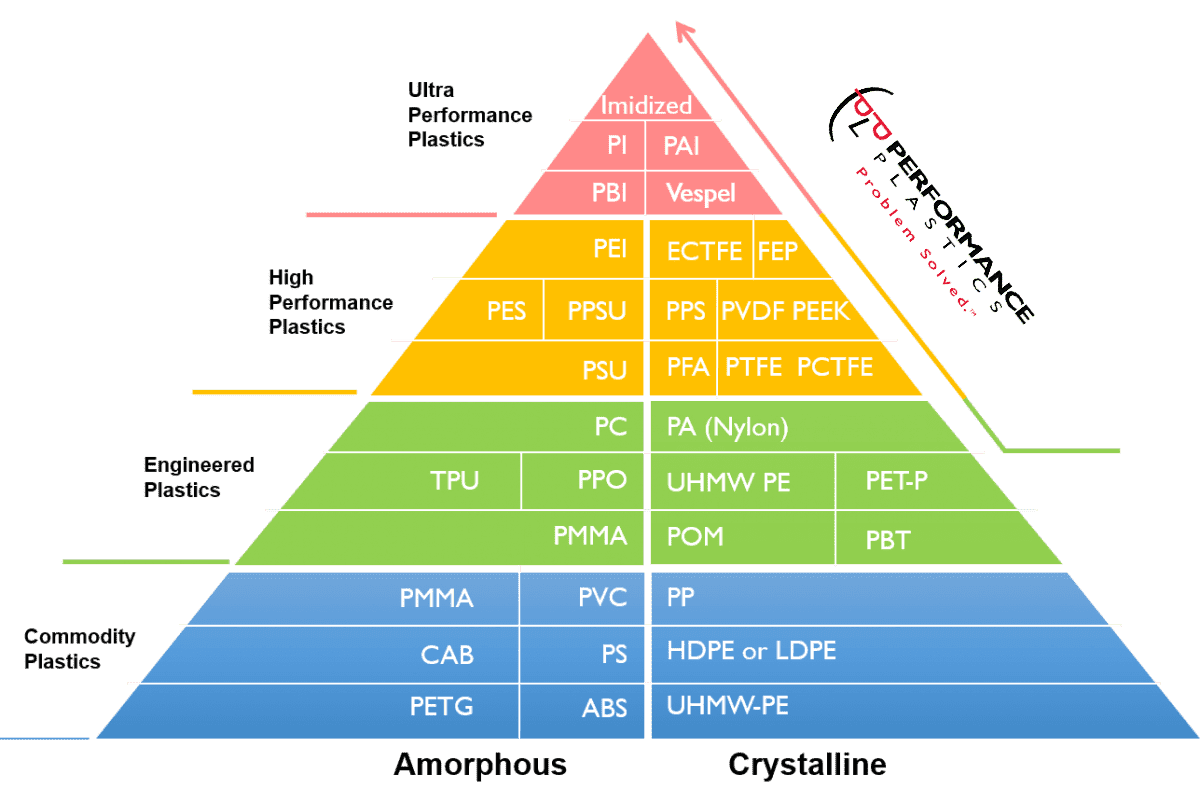

Plastics can be considered high-performance for a variety of reasons. The specific application and the performance criteria are the most important. Here are some characteristics that can contribute to a resin being classified as a high-performance plastic.

Plastics can be considered high-performance for a variety of reasons. The specific application and the performance criteria are the most important. Here are some characteristics that can contribute to a resin being classified as a high-performance plastic.