Precision and purity are vital to semiconductor production. Plastics assist in maintaining the standards necessary in production, ensuring that less time and resources are spent and that the items function properly.

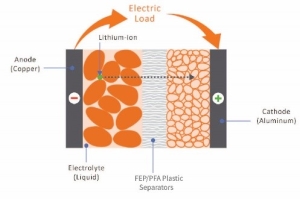

Unlike traditional materials like metal or ceramic, plastics such as FEP, PEEK, and PTFE are more impermeable to corrosive acids, which are key to the production of microchips.

High-performance plastics such as Fluorinated Ethylene Propylene (FEP), Polyether Ether Ketone (PEEK), and Polytetrafluoroethylene (PTFE), are characterized by their exceptional properties in different areas. High-performance plastics are largely used where the highest demands are placed on thermal or chemical resistance or product mechanics.

Microchips are primarily made from semiconducting materials such as silicon, not plastics. Silicon wafers undergo a complex series of processes including photolithography, etching, doping, and layering to create the intricate circuitry that forms the basis of microchips.

However, plastics do play a role in certain aspects of microchip manufacturing, and Performance Plastics, A Pexco Company, produces many of the necessary components.

- Components: Resins are used in various components used to manufacture microchips. This includes components of semiconductor manufacturing equipment, such as chambers, tubing, and fittings, which often utilize specialized plastic materials resistant to high temperatures and chemicals.

- Cleanroom Materials: In semiconductor fabrication facilities or cleanrooms, where microchips are produced, stringent cleanliness standards must be maintained to prevent contamination of the delicate semiconductor materials. Plastics are used extensively in cleanroom construction and furnishings due to their ease of cleaning, resistance to chemicals, and ability to meet cleanliness requirements.

- Chemical Handling: During the fabrication process, various chemicals are used for etching, doping, and cleaning semiconductor wafers. Plastics are often used for the storage, transport, and handling of these chemicals due to their chemical inertness and resistance to corrosion.

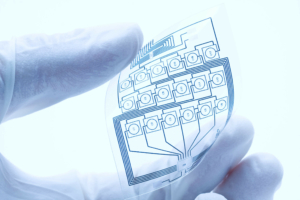

- Consumables: Plastics are used in the production of consumable items such as gloves, face masks, and packaging materials used in the handling and transportation of microchips and semiconductor wafers within the fabrication facility.

Overall, while plastics may not be directly visible in the final product of a microchip, they are indispensable in various stages of the microchip manufacturing process, contributing to its efficiency, reliability, and cost-effectiveness.

For more information on high-performance plastics such as FEP, PEEK, and/or PTFE, please don’t hesitate to get in touch with Rich Reed, Vice President of Sales & Marketing at [email protected], or visit our website at www.performance plastics.com

als, and poppets are key components of industrial applications used to seal joints, limit vibration, and prevent leaks. They serve critical functions, so it is essential to choose the correct material for the application. Performance Plastics has a thorough understanding of high-performance thermoplastics including PEEK, PFA, FEP, Torlon, and Ultem to create reliable, better sealing, longer wearing, and more cost-efficient components.

als, and poppets are key components of industrial applications used to seal joints, limit vibration, and prevent leaks. They serve critical functions, so it is essential to choose the correct material for the application. Performance Plastics has a thorough understanding of high-performance thermoplastics including PEEK, PFA, FEP, Torlon, and Ultem to create reliable, better sealing, longer wearing, and more cost-efficient components. Nylon® is a synthetic thermoplastic polyamide that is known for its strength, temperature resilience, and chemical compatibility. It has been proven to be a lightweight, heavy-duty industrial engineering plastic replacement for metals that are resistant to both heat and corrosive chemicals.

Nylon® is a synthetic thermoplastic polyamide that is known for its strength, temperature resilience, and chemical compatibility. It has been proven to be a lightweight, heavy-duty industrial engineering plastic replacement for metals that are resistant to both heat and corrosive chemicals.