Mating parts providing a fluid or gas seal are critical components in most mechanical systems. We commonly think of them in valves and connector assemblies, but they are also found in pressure vessels, compressors, pumps, motors, engines, transmissions, and almost all mechanical power trains. Seals, especially those that mate to moving parts, have a demanding set of quality requirements. Each application has its own specific needs, but all seals are characterized by tight dimensional tolerances and excellent surface finish.

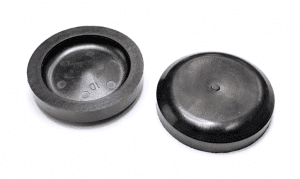

Our customer wanted to improve the usable life and leakage profile of a valve without absorbing any increase in component cost. The sealing surface specifications were tightened to 0.0005 inches (12.7 µ) which was key to accomplishing the performance improvements.

The previous supplier of this component was unable to meet the more stringent sealing surface dimensional tolerances “out of the mold” necessitating a finish machining operation to bring the part into tolerance. However, machining the sealing surface removed the resin-rich surface of the part creating micro-cracks in the surface and exposing reinforcing fibers. Both of these unavoidable consequences of machining negatively impacted component performance, useful life and cost.

Solution

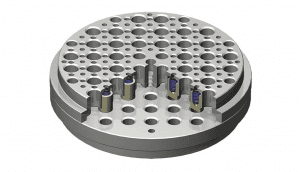

Performance Plastics knew eliminating the machining operation would improve strength, reduce trapped impurities, and lower manufacturing cost. Our engineering team focused on producing a “true net shape” part directly out of the mold. Key to accomplishing the customers goals involved leveraging our proprietary, iterative tool design process. It required making a 3D CT scan of preliminary molded parts measuring, in this case, approximately 1 million critical part dimensions. This analysis identified minute distortions. Utilizing internally developed proprietary software, PPL integrated the CT scan data with CAD/CAM software to make exacting mold modifications eliminating the out of tolerance conditions. This process contributed to producing a best in class “out-of-mold” conforming part.

The manufacturing process also had to be optimized to produce the desired performance results. Although the material posed molding challenges, PPL decided to direct gate the part at the top to ensure symmetry of material flow throughout the cavity, critical in achieving roundness to the sealing surface.

The results of development program surprised everyone. Performance Plastics was able to achieve “out of mold” net shape parts with a seal surface capable of meeting sealing ranges of 100 psi to 3,000 psi, with no porosity and consistently meeting dimensional tolerances of 0.0003 inches, or 7.62 µ. Eliminating the need for subsequent finish machining dropped the leakage rate for the valve by 50%, from 1.0 scfm to 0.5 scfm.

At Performance Plastics, we are experts in injection molding, specializing in high performance plastics. Our proprietary tool design software, processes and equipment enable us to injection mold components having complex geometries made from challenging ultra, high-performance thermoplastic materials, and reinforced compounds. For more information on Performance Plastic’s capabilities, please contact Rich Reed, Vice President of Sales and Marketing at 513.321.8404 or email at [email protected]