What is a high-performance plastic?

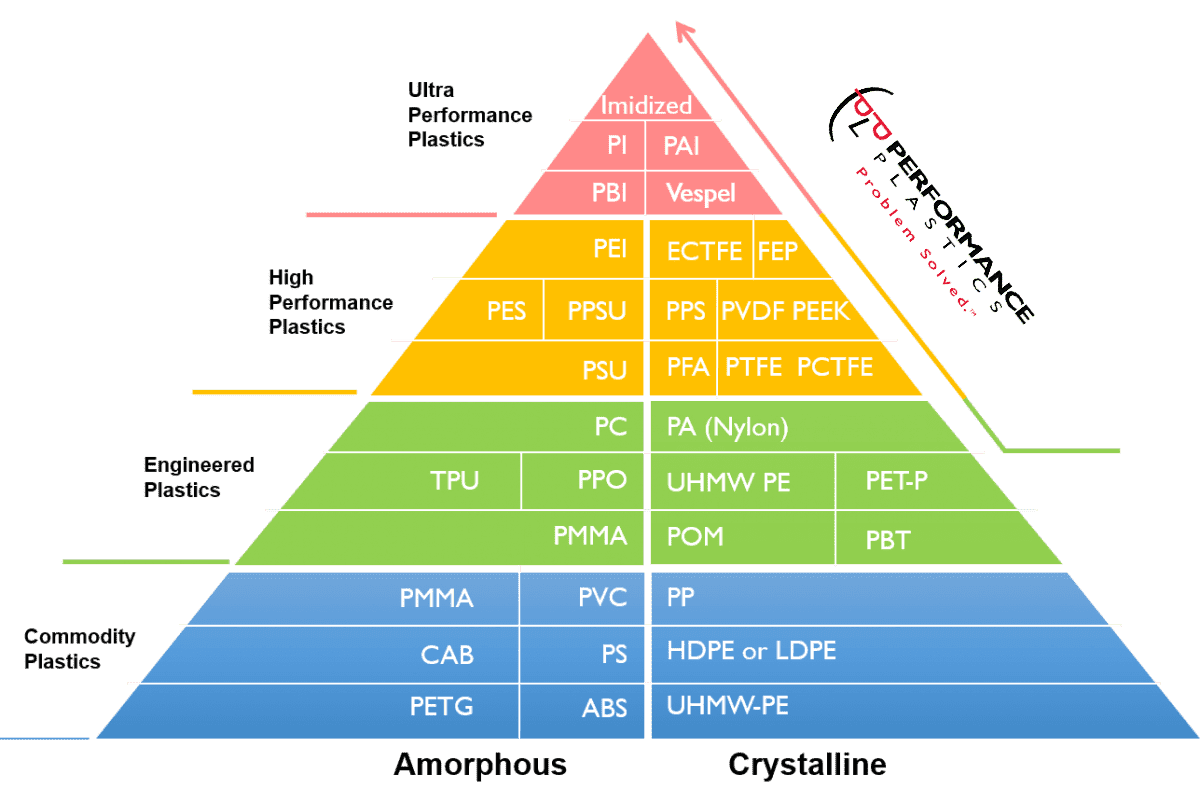

February 28, 2023 | Blog, Materials Blogs, Precision Injection Molding Capabilities Blogs, Videos Plastics can be considered high-performance for a variety of reasons. The specific application and the performance criteria are the most important. Here are some characteristics that can contribute to a resin being classified as a high-performance plastic.

Plastics can be considered high-performance for a variety of reasons. The specific application and the performance criteria are the most important. Here are some characteristics that can contribute to a resin being classified as a high-performance plastic.

- Strength and durability: Many plastics are engineered (fiber reinforced) to be extremely strong and durable, with high tensile strength and resistance to wear, tear, and impact. This can make them well-suited for applications where mechanical stress is a concern. Examples include Torlon PAI and PEEK.

- Temperature resistance: Certain plastics are highly resistant to chemical corrosion or degradation, which can make them ideal for use in harsh environments or with corrosive substances. Examples include fluoropolymers such as PFA with a melting point of 581 degrees F.

- Electrical properties: Some plastics have excellent electrical insulation properties, making them ideal for use in electronics or other electrical applications. Examples include fluoropolymers such as FEP.

- Lightweight: Many plastics are lightweight, which can make them ideal for applications where weight is a concern, such as the aerospace, medical, or industrial markets.

- Versatility: Plastics can be easily injection molded into a wide variety of complex shapes and sizes, which can make them versatile and useful in a wide range of applications.

Overall, high-performance plastics can be custom designed to meet specific performance criteria and offer a wide range of benefits depending on the application.

For more information on high-performance plastics or other Performance Plastics services, please contact Rich Reed, Vice President of Sales & Marketing at [email protected] or call 440-785-7122.