Having a mold made is a large investment for any size company. Running between $30,000 to $70,000, molds are an investment that need to be reliable the first time, all the time.

But it seems more and more, Performance Plastics is seeing customers looking to transfer their molds because those molds can’t achieve company goals. This blog explores our history of transferring molds made by others to us and how our processing expertise pays off for customers in the long run.

Why Transfer?

“One of our customers has a mold that makes 1 million parts per year for a critical application, but they weren’t getting consistent production from their previous supplier,” says Chris Lawson, chief operating officer at Performance Plastics. “They were worried about the inconsistency of their supply and if that would translate into failure in the field.”

The main reason for transferring a mold from one supplier to another comes down to the supplier’s expertise in using the mold. Generally, the customer isn’t seeing consistency in the parts coming out of the mold and knows that something is missing in the strategy – but they’re not sure what.

“At least half of the customers we currently have started out by transferring their mold to us,” Lawson says.

The Handoff

Like so many others, that million-part customer reached out to Performance Plastics to discuss mold transfer. But the process doesn’t begin with packing the mold into a crate and shipping it to our Cincinnati offices. It starts with defining the problem.

“Does the customer understand why they’re not getting the type of product they need, and do they understand what they perceive the product to be?” Lawson asks. “We spend time with the customer trying to understand what the product should do; what does the customer believe is critical.”

For example, a customer might need “Diameter A” to be perfect. However, production of the mold was driven more by some other product feature.

“We have to understand what’s important to them and why they aren’t getting it out of the product,” Lawson says. “We try to define the problem, where most can only identify the symptoms.”

Once the problem is defined and the mold is transferred, Performance Plastics gets to work … and that starts with running the mold as though it came in new.

“We just want to see what happens with it,” Lawson says. “Sometimes the previous supplier just didn’t follow a robust approach in working with the mold and missed something. We can identify that.”

Performance Plastics uses everything from basic scientific injection molding principles to design of experiment (DOE) concepts. DOE is a branch of applied statistics that deals with planning, conducting, analyzing, and interpreting controlled tests to evaluate the factors that control the value of a parameter or group of parameters. It is a powerful data collection and analysis tool that can be used in a variety of experimental situations.

“Most people don’t understand DOE when they are testing something,” Lawson says. “You’re trying to understand how five different factors interrelate to results that you believe are important, and that’s where we specialize.”

The Transfer Process

Transferring a mold from one supplier to another can take between two and six weeks – although Performance Plastics has done it in as little as three days!

“Once we get our process engineers involved, we can move rather quickly,” Lawson says. “It just depends on if any changes need to be made to the mold itself.”

Performance Plastics has three toolmakers in house that can handle mold modifications to correct errors, and to create fixtures and robotic end effectors if needed.

A lot of the timing revolves around the customer’s ability to supply their own customers. Because the mold is already in use and contracts have been signed, customers need to keep up their inventory of parts to meet demand, all while working to transfer the mold to another supplier who can use it more effectively.

“We understand that it’s painful to transfer suppliers,” Lawson said. “That said, we’ve handled more than 150 mold transfers over the years, and we have the expertise a lot of people are missing.”

To learn more about how Performance Plastics can help transfer your mold, contact Rich Reed, our Vice President of Sales and Marketing, at (513) 321-8404 or [email protected].

High-Performance Plastic Bearings

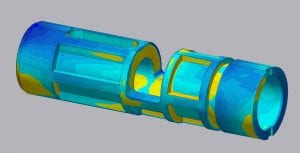

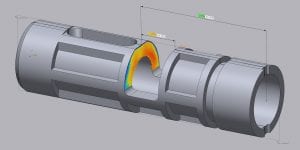

High-Performance Plastic Bearings Industrial CT scanning gives customers access to the inner workings of a part without having to destroy the original. The scanner rotates the part 360 degrees and uses X-rays to create a precise 3D model. This allows for a thorough analysis of object dimensions, porosity, wall thickness, assembly defects, comprehensive comparisons, and reverse engineering.

Industrial CT scanning gives customers access to the inner workings of a part without having to destroy the original. The scanner rotates the part 360 degrees and uses X-rays to create a precise 3D model. This allows for a thorough analysis of object dimensions, porosity, wall thickness, assembly defects, comprehensive comparisons, and reverse engineering. High performance plastic materials have ideal properties when it comes to durability. Plastics like polytetrafluoroethylene (PTFE/Telfon®) are known for their dielectric strength, low dissipation, chemical resistance, outstanding performance at elevated temperatures, and coefficient friction. However, their unique properties can make machining PFTE quite difficult. Dimensional changes, burrs, and consistency of machining can all be factors when you are creating a part out of these materials. Performance Plastics has found a way around the complications of machining PTFE by injection molding of other fluoropolymers.

High performance plastic materials have ideal properties when it comes to durability. Plastics like polytetrafluoroethylene (PTFE/Telfon®) are known for their dielectric strength, low dissipation, chemical resistance, outstanding performance at elevated temperatures, and coefficient friction. However, their unique properties can make machining PFTE quite difficult. Dimensional changes, burrs, and consistency of machining can all be factors when you are creating a part out of these materials. Performance Plastics has found a way around the complications of machining PTFE by injection molding of other fluoropolymers. tool design software, processes and equipment enabling us to injection mold components having complex geometries made from challenging ultra- and high-performance thermoplastic materials and highly loaded compounds. We utilize a unique combination of extensive material knowledge, mold flow analysis, a design system and process expertise to eliminate or minimize the need for secondary operations.

tool design software, processes and equipment enabling us to injection mold components having complex geometries made from challenging ultra- and high-performance thermoplastic materials and highly loaded compounds. We utilize a unique combination of extensive material knowledge, mold flow analysis, a design system and process expertise to eliminate or minimize the need for secondary operations. they can select the right material and adjust the integrating ribs or gussets. With the vast variety of materials and colors, making your color options almost endless.

they can select the right material and adjust the integrating ribs or gussets. With the vast variety of materials and colors, making your color options almost endless.

lightweight and resistant to corrosion.

lightweight and resistant to corrosion.