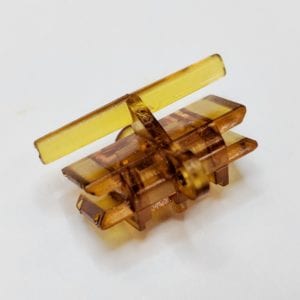

Ultem PEI Polyetherimide thermoplastic component

High performance plastics are plastics that meet higher requirements than standard or engineering plastics. Generally, they are used in smaller amounts for critical applications such as aerospace, defense, medical or industrial applications. They represent about 1% of the plastics manufactured worldwide. High performance plastics differ from standard plastics primarily by their higher thermal stability, outstanding chemical resistance, and superior product quality.

There are many names for the term high-performance plastics, such as: high temperature plastics, high performance polymers, high performance thermoplastics or high tech plastics. The term “polymers” is often used instead of “plastics” when referring to a high performance plastic. Performance plastics are often achieved by the addition of stabilizers and reinforcing materials such as glass and carbon fibers to increase the degree of polymerization.

When it comes to thermal stability, high performance plastics generally have an operating temperature over 300ºF. One material, PEEK, can hold a continuous operating temperature of 500ºF, while another called Celazole® PBI has a continuous service capability of 750ºF. High performance plastics won’t deform or degrade in high temperature applications and maintain their superior mechanical properties.

High performance plastics also offer outstanding chemical resistance. PPS, FEP/PFA and PAI are resistant to a broad range of chemicals while Teflon® (PTFE) is almost entirely chemically inert and highly insoluble in most solvents or chemicals.

High performance plastics offer superior product quality in terms of machinability, durability, reusability, and recyclable qualities. They are used in a wide range of multi-use applications and durable applications and are frequently used to replace other materials such as metal, wood, and glass. Nearly all high performance plastics are recyclable.

The superior product quality of high-performance plastics (specifically their high heat resistance and strength/stiffness) can make them difficult to process, often requiring specialized machinery and talent. This, combined with their higher material cost, generally restrict their use to specialized applications. However, their capabilities and outstanding performance make high-performance plastic parts well worth the cost. For more information on high performance plastics or other Performance Plastics services, please contact Rich Reed, Vice President of Sales & Marketing at [email protected] or call 440-785-7122.

Performance Plastics is a leader in providing innovative production solutions for our customers. We have the opportunity to work on many new projects annually and follow a process guideline called our “Project Development Roadmap”. This process is formatted in a way that everyone involved has a clear view and set expectations.

Performance Plastics is a leader in providing innovative production solutions for our customers. We have the opportunity to work on many new projects annually and follow a process guideline called our “Project Development Roadmap”. This process is formatted in a way that everyone involved has a clear view and set expectations.

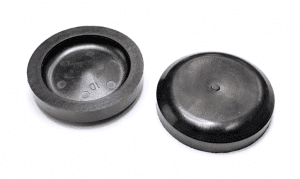

For four decades, Performance Plastics has been delivering the highest quality custom plastic injection molding solutions in the industry for our customers. We take a highly specialized and consultative approach, working closely with our customers to develop the solutions needed to solve the most complicated issues.

For four decades, Performance Plastics has been delivering the highest quality custom plastic injection molding solutions in the industry for our customers. We take a highly specialized and consultative approach, working closely with our customers to develop the solutions needed to solve the most complicated issues.