Performance Plastics Improves Compressor Valve Performance With Poppets Made From VICTREX® PEEK™ Polymer

Manufacturers of check valves and pressure relief valves for hydraulic and pneumatic compressors are constantly looking for ways to improve the performance of their products. Valve performance, more than any other component, determines compressor efficiency.

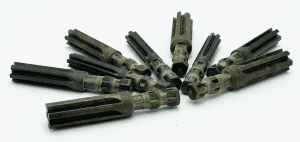

To achieve reduction in fluid leakage, noise and cost, and extended valve life, Performance Plastics (PPL), recommends replacing the metal poppets with poppets made of VICTREX® PEEK™ polymer, a high performance thermoplastic. Experience has shown that converting to a poppet made from VICTREX PEEK polymer provides tremendous improvements in productivity.

ALLOWS WIDER OPERATING RANGE

One of the major benefits of using VICTREX PEEK polymer is that it allows the valves to operate in high and low pressure applications. It increases the number of applications in which valves and compressors can be used.

SUPERIOR IMPACT RESISTANCE

VICTREX PEEK POLYMER —

Ideal Replacement for Metal Poppets

Metal poppets have always posed a number of challenges. They can be difficult and costly to machine and the sealing surface can be inconsistent due to difficulties in machining defect-free seat surfaces.

As a replacement for metal, VICTREX PEEK high performance polymer is an engineering solution due to its outstanding combination of properties. Substituting plastic for metal maintains strength while improving corrosion resistance, reducing weight, and allowing for greater design flexibility.

Another benefit of using VICTREX PEEK polymer is its superior impact resistance. According to Performance Plastics, one of the primary reasons why valves fail are the fissures brought on by repeated impact pressure. PPL has had applications where VICTREX PEEK polymer has passed two million impact cycles and another where it has passed 20 million impact cycles.

BETTER SEALING AND WEAR RESISTANCE

Because VICTREX PEEK polymer is compliant and can conform to the mating seat surface, it provides better sealing performance and less leakage than metal poppets. It also offers excellent wear resistance and improved wear conditions on the mating seat surface. Wear and damage to the mating seat surface is a big issue with metal poppets and re-work of pumps and valve assemblies is both costly and time consuming on the production line.

PROPERTIES OF VICTREX PEEK POLYMER

- High Temperature Resistance — Can withstand continuous operating temperatures of up to 260°C (500°F). Also maintains short-term mechanical properties at temperatures approaching its melting point of 340°C (644°F).

- Wear Resistance — Outstanding wear resistance over wide ranges of pressure, velocity, temperature and counterfacial

- Mechanical Properties — Excellent strength, stiffness and long-term properties, such as creep and fatigue, retained over a wide range of temperatures and

- Chemical Resistance — Exhibits outstanding resistance to a wide range of chemical and corrosive environments, even at elevated temperatures up to 200°C (392°F).

- Hydrolysis Resistance — Retains high levels of mechanical properties and dimensional stability when continuously operating in water, brine or steam at elevated temperatures and

- Dimensional Stability — Remarkably stable, resisting changes to its properties due to temperature, moisture, chemical attack or physical

METAL REPLACEMENT APPLICATIONS

Metal to plastic conversions and metal part replacement applications are areas of expertise at Performance Plastics. Because of its superb all-around properties, Performance Plastics has used VICTREX PEEK polymer successfully in many metal replacement applications including:

- A poppet made with VICTREX PEEK polymer replaced a two-piece metal assembly, resulting in a significant cost reduction. It also improved initial product quality and reduced customer valve rework from 200 units per month to less than

- Poppets made with VICTREX PEEK polymer provided more sensitivity than the metal poppets, resulting in more consistent pressure relief actuation performance. The plastic poppets also provided a lower noise level than the metal

SUMMARY

Performance Plastics is confident that their experience and proven track record in the high performance area can greatly benefit customers by solving some of their most difficult applications.

Victrex is an innovative leading manufacturer of high performance polyketones, including VICTREX® PEEK™ polymer, VICOTE® Coatings and APTIV™ film.

These materials are used in a variety of markets and offer an exceptional combination of properties to help processors and end users reach new levels of cost savings, quality and performance. All Victrex material production comes under Victrex’s ISO 9001 quality registration.

Victrex USA, Inc.

300 Conshohocken State Road Suite 120

West Conshohocken, PA 19428 USA

Tel: + (1) 800-VICTREX Tel: + (1) 484-342-6001

Fax: + (1) 484-342-6002

Email: [email protected] www.victrex.com

Performance Plastics, Ltd., is one of the pioneer molders specializing in injection molding high performance plastics, and other high performance resins. The company develops innovative, cost effective manufacturing solutions for applications that require highly engineered plastics, sophisticated part geometry, tight tolerances, and technical expertise.

Performance Plastics, Ltd.

4435 Brownway Avenue

Cincinnati, OH 45209

USA Tel: + (1) 513 321-8404

Fax: + (1) 513 321-0288

Email: [email protected] www.performanceplastics.com

VICTREX PLC BELIEVES THAT THE INFORMATION CONTAINED IN THIS BROCHURE IS AN ACCURATE DESCRIPTION OF THE TYPICAL CHARACTERISTICS AND/OR USES OF THE PRODUCT OR PRODUCTS, BUT IT IS THE CUSTOMER’S RESPONSIBILITY TO THOROUGHLY TEST THE PRODUCT IN EACH SPECIFIC APPLICATION TO DETERMINE ITS PERFORMANCE, EFFICACY AND SAFETY FOR EACH END-USE PRODUCT, DEVICE OR OTHER APPLICATION. SUGGESTIONS OF USES SHOULD NOT BE TAKEN AS INDUCEMENTS TO INFRINGE ANY PARTICULAR PATENT. THE INFORMATION AND DATA CONTAINED HEREIN ARE BASED ON INFORMATION WE BELIEVE RELIABLE. MENTION OF A PRODUCT IN THIS DOCUMENTATION IS NOT A GUARANTEE OF AVAILABILITY. VICTREX PLC RESERVES THE RIGHT TO MODIFY PRODUCTS, SPECIFICATIONS AND/OR PACKAGING AS PART OF A CONTINUOUS PROGRAM OF PRODUCT DEVELOPMENT.

VICTREX PLC MAKES NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, WITHOUT LIMITATION, A WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE OR OF INTELLECTUAL PROPERTY NON-INFRINGEMENT, INCLUDING, BUT NOT LIMITED TO PATENT NON-INFRINGEMENT, WHICH ARE EXPRESSLY DISCLAIMED, WHETHER EXPRESS OR IMPLIED, IN FACT OR BY LAW. FURTHER, VICTREX PLC MAKES NO WARRANTY TO YOUR CUSTOMERS OR AGENTS, AND HAS NOT AUTHORIZED ANYONE TO MAKE ANY REPRESENTATION OR WARRANTY OTHER THAN AS PROVIDED ABOVE. VICTREX PLC SHALL IN NO EVENT BE LIABLE FOR ANY GENERAL, INDIRECT, SPECIAL, CONSEQUENTIAL, PUNITIVE, INCIDENTAL OR SIMILAR DAMAGES, INCLUDING WITHOUT LIMITATION, DAMAGES FOR HARM TO

BUSINESS, LOST PROFITS OR LOST SAVINGS, EVEN IF VICTREX HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES, REGARDLESS OF THE FORM OF ACTION.

VICTREX® is a registered trademark of Victrex Manufacturing Limited. PEEK™, PEEK-HT™ and APTIV™ are trademarks of Victrex plc. VICOTE® is a registered trademark of Victrex plc.

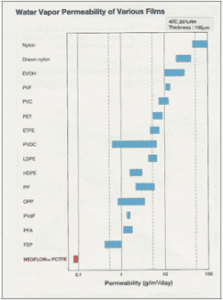

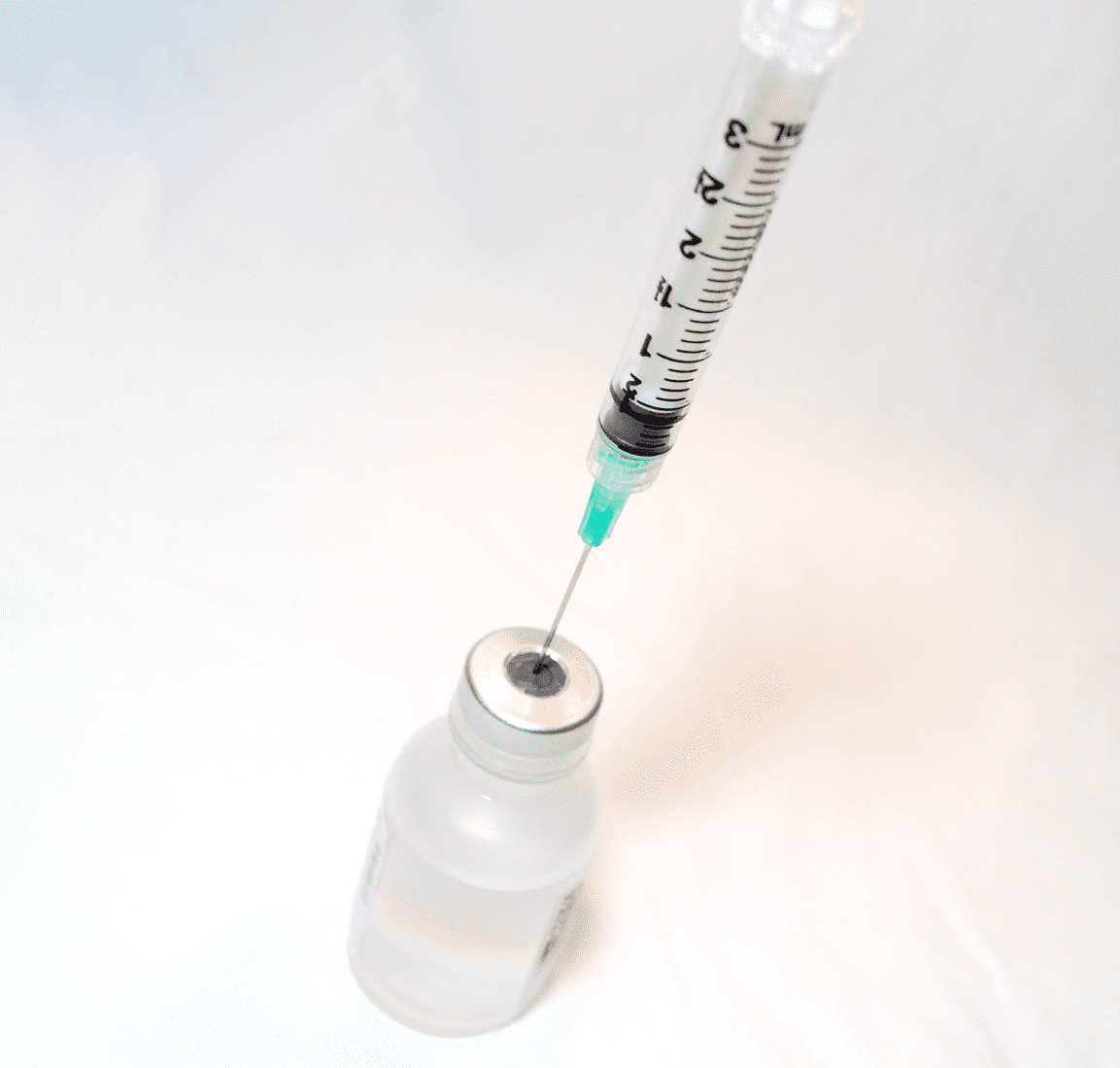

The shortage in glass has been an ongoing issue. This year with restaurants and bars being closed we have seen a greater shortage in the glass industry. The collection of wine and beer bottles from restaurants contributes to a large volume of recycled glass needed to meet demands. The glass shortage affects all industries that rely on glass for their containers, but right now the medical field is in dire need of glass for vials.

The shortage in glass has been an ongoing issue. This year with restaurants and bars being closed we have seen a greater shortage in the glass industry. The collection of wine and beer bottles from restaurants contributes to a large volume of recycled glass needed to meet demands. The glass shortage affects all industries that rely on glass for their containers, but right now the medical field is in dire need of glass for vials. stick, ensuring product does not adsorb to surfaces. They are also virtually impervious to chemical, enzyme and microbiological attack. All the benefits of FEP, PFA, and PCTFE make these fluoropolymers a perfect material to create vials out of, especially since they are injection moldable.

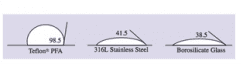

stick, ensuring product does not adsorb to surfaces. They are also virtually impervious to chemical, enzyme and microbiological attack. All the benefits of FEP, PFA, and PCTFE make these fluoropolymers a perfect material to create vials out of, especially since they are injection moldable. Covid-19 has impacted our world in more ways than one. The ability to keep your office, workspace, and your whole environment sanitized has increased greatly. The use of cleaning supplies for sanitation increases depending on the type of surface that you are sanitizing. Some surfaces are more porous than others needing to be sanitized more often to maintain a clean environment. At Performance Plastics, we deal with different types of plastics every day, making us experts in various materials that excel in a clean environment.

Covid-19 has impacted our world in more ways than one. The ability to keep your office, workspace, and your whole environment sanitized has increased greatly. The use of cleaning supplies for sanitation increases depending on the type of surface that you are sanitizing. Some surfaces are more porous than others needing to be sanitized more often to maintain a clean environment. At Performance Plastics, we deal with different types of plastics every day, making us experts in various materials that excel in a clean environment.