PEEK or polyetheretherketone belongs to a family of polymers called polyketones or iPAEKs. This means that is it built from the following building blocks:

PEEK is one of the highest performing thermoplastics in the world. Compared to metals, PEEK based materials are very light weight, easily shaped, resistant to corrosion and have considerably higher specific strength (strength per unit weight).

PEEK is optimal for aerospace applications because although it is a thermoplastic, it boasts heat resistance, little to no reaction against harmful chemicals and radiation, and comparable tensile and load strength to that of titanium and steel while being many times lighter.

PEEK® does not offer merely two or three properties that mark it as the polymer of choice for aerospace/defense; it has a whole variety of them. They include:

Tests have shown that PEEK polymer has a continuous use temperature of 260°C (500°F). This can make it suitable for use in a wide range of thermally aggressive environments. PEEK tolerates friction and resists wear in dynamic applications like thrust washers and seal rings.

PEEK resists the damage that can be inflicted in chemically aggressive operational environments. It can resist jet fuel, hydraulic fluids, de-icers and insecticides used in the aerospace industry. This holds true over wide ranges of pressure, temperature, and time.

PEEK offers excellent strength and stiffness over a wide temperature range. PEEK-based composites have specific strength many times that of metals and alloys. “Creep” refers to a material becoming permanently deformed over an extended period when under constant applied stress. “Fatigue” refers to the brittle failure of a material under a repeated cyclic loading. PEEK has both high creep and fatigue resistance thanks to its semi-crystalline structure and has been shown to be more durable than many other polymers and some metals over a long and useful lifetime.

- Difficult to ignite or burn

PEEK has excellent flammability performance. It resists combustion up to almost 600°C. When it can be made to burn at very high temperatures, it will not support combustion and it emits little smoke. This is one reason why PEEK is widely used in commercial aircraft.

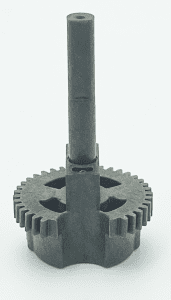

Aerospace/defense part manufacturers now use PEEK as a way to improve the weight and durability of their parts. PEEK is a standard high-performance plastics in the aerospace/defense industry applications.

Performance Plastics’ team of experienced engineers possess the expertise to design and manufacture technically challenging projects and offer complex solutions within the aerospace/defense industries.

For more information on how Performance Plastics can assist in your material selection challenges, please contact Rich Reed, VP Sales & Marketing at 513.321.8404 or [email protected].