The quality behind your product as a manufacturer is the key to long-term success. At Performance Plastics, we hold the quality of our products to the highest standards. We know that quality is critical to satisfying our customers and retaining their loyalty. For this reason, we go above and beyond to make sure our customers products are no less than perfect.

The quality behind your product as a manufacturer is the key to long-term success. At Performance Plastics, we hold the quality of our products to the highest standards. We know that quality is critical to satisfying our customers and retaining their loyalty. For this reason, we go above and beyond to make sure our customers products are no less than perfect.

Manufacturing quality products make an important contribution to having long term relationships with your customers. Taking the extra time after injection molding a product to test the quality and compliance standards is a key value for us. We will go above and beyond to make sure we are meeting all standards for your product. The most recent standard we have achieved attaining SEMI F57 compliance for one of our customers PFA (Perfluoroalkoxy) injection molded products.

SEMI F57 compliance is a specification for polymer materials and components used in ultrapure water and liquid chemical distribution systems. The SEMI F57 standard requires fluid-component manufacturers to follow best practices in material science and not contaminate UHP processes with extractable ions, metallics or total organic  carbon (TOC). The standard also covers surface roughness, particle contribution, metallic contamination, and reliability testing.

carbon (TOC). The standard also covers surface roughness, particle contribution, metallic contamination, and reliability testing.

In order to ensure that our customers product maintains SEMI F57 compliance, we have added new quality testing steps to ensure the product is up to par. This quality test is crucial to our customer. It certifies that each product injection molded by Performance Plastics follows the SEMI F57 standards and will not contaminate ultrapure water and liquid chemical distribution systems.

For more information on how Performance Plastics can help your injection molded PFA product achieve SEMI F57 compliance, contact Rich Reed for our Vice President of Sales and Marketing, at (513) 321-8404 or [email protected].

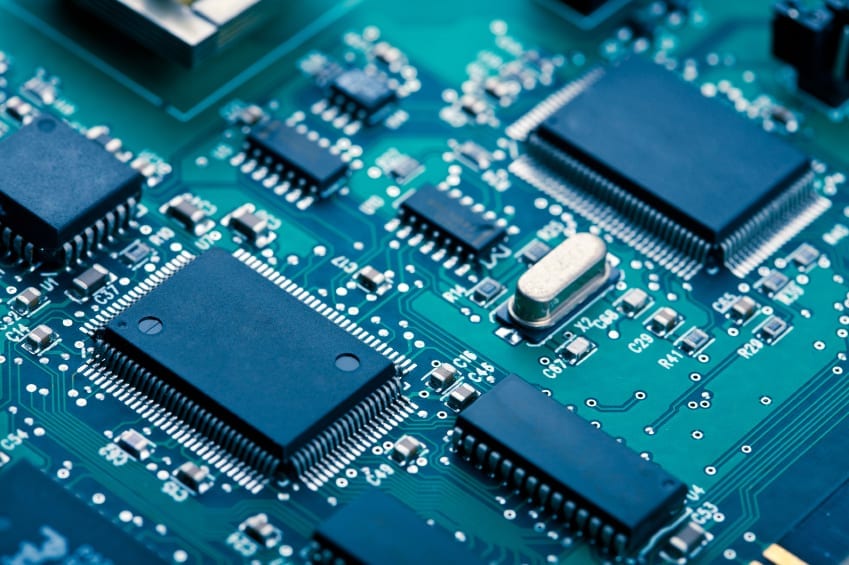

High performance injection molded plastics have been replacing metal in various applications. The transition from metal to high performance plastics has given engineers more freedom in their designs, while also increasing their products durability. The use of high-performance plastics has created more opportunities in the aerospace, automotive, electronic, and energy industries. High-performance plastics have not only allowed these industries to decrease the weight of their products, but also helped to create smarter products.

High performance injection molded plastics have been replacing metal in various applications. The transition from metal to high performance plastics has given engineers more freedom in their designs, while also increasing their products durability. The use of high-performance plastics has created more opportunities in the aerospace, automotive, electronic, and energy industries. High-performance plastics have not only allowed these industries to decrease the weight of their products, but also helped to create smarter products. range for thermal management. The increase in thermal management allows for improved heat sinks and heat removal applications, creating enhanced performance and reliability.

range for thermal management. The increase in thermal management allows for improved heat sinks and heat removal applications, creating enhanced performance and reliability. The aerospace industry has seen a lot of change this year. Effects of Covid-19 keeping planes on the ground and the push to move to a zero-waste philosophy has created a new perspective. The need to watch budgets and recycle all parts of the plane has become a greater priority. This change is increasing aircraft maintainers need for non-marring aircraft maintenance tools.

The aerospace industry has seen a lot of change this year. Effects of Covid-19 keeping planes on the ground and the push to move to a zero-waste philosophy has created a new perspective. The need to watch budgets and recycle all parts of the plane has become a greater priority. This change is increasing aircraft maintainers need for non-marring aircraft maintenance tools.

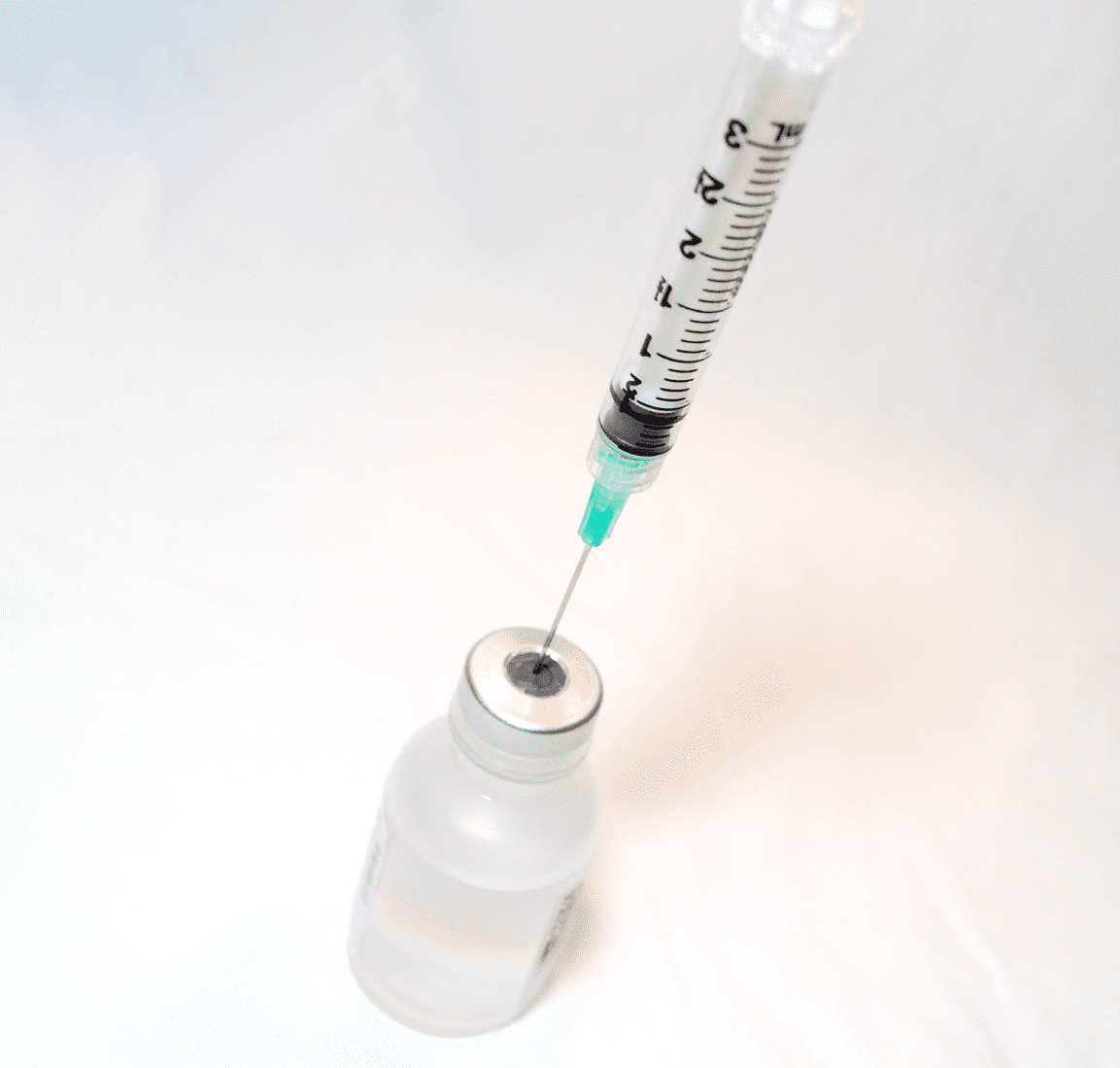

The shortage in glass has been an ongoing issue. This year with restaurants and bars being closed we have seen a greater shortage in the glass industry. The collection of wine and beer bottles from restaurants contributes to a large volume of recycled glass needed to meet demands. The glass shortage affects all industries that rely on glass for their containers, but right now the medical field is in dire need of glass for vials.

The shortage in glass has been an ongoing issue. This year with restaurants and bars being closed we have seen a greater shortage in the glass industry. The collection of wine and beer bottles from restaurants contributes to a large volume of recycled glass needed to meet demands. The glass shortage affects all industries that rely on glass for their containers, but right now the medical field is in dire need of glass for vials. stick, ensuring product does not adsorb to surfaces. They are also virtually impervious to chemical, enzyme and microbiological attack. All the benefits of FEP, PFA, and PCTFE make these fluoropolymers a perfect material to create vials out of, especially since they are injection moldable.

stick, ensuring product does not adsorb to surfaces. They are also virtually impervious to chemical, enzyme and microbiological attack. All the benefits of FEP, PFA, and PCTFE make these fluoropolymers a perfect material to create vials out of, especially since they are injection moldable.

Covid-19 has impacted our world in more ways than one. The ability to keep your office, workspace, and your whole environment sanitized has increased greatly. The use of cleaning supplies for sanitation increases depending on the type of surface that you are sanitizing. Some surfaces are more porous than others needing to be sanitized more often to maintain a clean environment. At Performance Plastics, we deal with different types of plastics every day, making us experts in various materials that excel in a clean environment.

Covid-19 has impacted our world in more ways than one. The ability to keep your office, workspace, and your whole environment sanitized has increased greatly. The use of cleaning supplies for sanitation increases depending on the type of surface that you are sanitizing. Some surfaces are more porous than others needing to be sanitized more often to maintain a clean environment. At Performance Plastics, we deal with different types of plastics every day, making us experts in various materials that excel in a clean environment.

The manufacturing world has been under a great amount of stress from effects of the Corona Virus. COVID-19 put a dent into companies everyday work flow. The ability to purchase items from other countries and the way your company operates has been altered. All this change caused serious brainstorming, to find a way around the roadblocks put into place by COVID-19. The biggest roadblock for the injection molding industry has been how to continue running when your mold has been delayed from the virus’s effects on China’s import and export of goods.

The manufacturing world has been under a great amount of stress from effects of the Corona Virus. COVID-19 put a dent into companies everyday work flow. The ability to purchase items from other countries and the way your company operates has been altered. All this change caused serious brainstorming, to find a way around the roadblocks put into place by COVID-19. The biggest roadblock for the injection molding industry has been how to continue running when your mold has been delayed from the virus’s effects on China’s import and export of goods. company’s situation is different, but do not let the idea of transferring your mold back to the U.S. scare you.

company’s situation is different, but do not let the idea of transferring your mold back to the U.S. scare you.