EnduroSharp® has changed the way maintenance professionals remove sealants and adhesives from composite substrates and fasteners. EnduroSharp® tools are made from Torlon®, a high strength, high performance plastic polymer which provides all the benefits of a sharp tool without the risk associated with caustic devices.

EnduroSharp® has changed the way maintenance professionals remove sealants and adhesives from composite substrates and fasteners. EnduroSharp® tools are made from Torlon®, a high strength, high performance plastic polymer which provides all the benefits of a sharp tool without the risk associated with caustic devices.

EnduroSharp® Torlon® maintenance tools are non metallic scraper tools designed to hold a superior edge but not damage composite structures like aluminum, fiberglass and carbon fibers. Constructed from a custom polyamidimide blend (PAI), they are durable, nonmetallic blades designed to remove elastomeric coatings, protective boots, tapes, sealants and adhesive residue and gap filler materials.

Composite materials are made of two or more materials with different physical or chemical properties that when combined, do not fully blend but together become stronger and more durable. Materials used in composites include resins of glass fiber, reinforced polyester, reinforced epoxy, carbon fibers, graphite and blends of metals. Combining the materials produce components that are strong, lightweight, corrosion resistant and dimensionally stable. They feature high rigidity and resistance to to torsion and fatigue with good flexibility, corrosion resistant and reduced weight.

EnduroSharp® is an improvement over existing nonmetallic scrapers due to the Torlon® stiffness and edge design. Torlon® holds the cutting longer, is easier to sharpen and is machinable to configure. Torlon® is a high strength, high temperature polymer that is injection molded and oven “cured” to produce the highest tensile strength. It posses features that are ideal in that they hold an effective, resharpenable edge but not pose a threat to composite structures It is an easy to use, will less effort for tough materials and deeper gaps. The tool is ideal for tighter edges, and is designed to remove adhesives, sealants and coatings from low weight, design flexible structures.

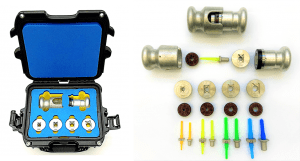

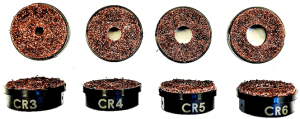

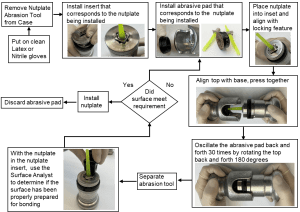

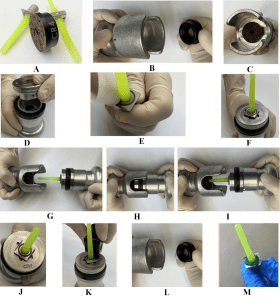

The EnduroSharp® lineup consists of a variety of scraper blades, gap blades, reamers, cutter, bits, and discs for removal of substances on composite aircraft and composite windmill blades.

Performance Plastics is a custom injection molder of high performance, tight tolerance thermoplastic components. We specialize in geometrically complex precision parts that consist of chemically inert materials.

For more information on the EnduroSharp® product line, please contact Rich Reed at [email protected] or our website at www.performanceplastics.com

EnduroSharp® has changed the way maintenance professionals remove sealants and adhesives from composite substrates and fasteners. EnduroSharp® tools are made from Torlon®, a high strength, high performance plastic polymer which provides all the benefits of a sharp tool without the risk associated with caustic devices.

EnduroSharp® has changed the way maintenance professionals remove sealants and adhesives from composite substrates and fasteners. EnduroSharp® tools are made from Torlon®, a high strength, high performance plastic polymer which provides all the benefits of a sharp tool without the risk associated with caustic devices.

The aerospace industry has seen a lot of change this year. Effects of Covid-19 keeping planes on the ground and the push to move to a zero-waste philosophy has created a new perspective. The need to watch budgets and recycle all parts of the plane has become a greater priority. This change is increasing aircraft maintainers need for non-marring aircraft maintenance tools.

The aerospace industry has seen a lot of change this year. Effects of Covid-19 keeping planes on the ground and the push to move to a zero-waste philosophy has created a new perspective. The need to watch budgets and recycle all parts of the plane has become a greater priority. This change is increasing aircraft maintainers need for non-marring aircraft maintenance tools.