Performance Plastics – Problem Solved – has updated our EnduroSharp® website with a 24/7 ecommerce portal that makes finding and ordering your EnduroSharp® products even easier.

Performance Plastics – Problem Solved – has updated our EnduroSharp® website with a 24/7 ecommerce portal that makes finding and ordering your EnduroSharp® products even easier.

Performance Plastics is a leader in high performance plastics engineering. Our customers include many of the industry’s leading companies in aerospace, medical and industrial applications. We execute mission critical projects where failure is not an option.

“We’re in the age of eCommerce,” said Chris Lawson, COO of Performance Plastics. “Many B2B companies have accelerated their digital strategy following the onset of the pandemic. COVID 19 has fundamentally altered purchasing behaviors and our buyer’s needs and timelines. We want to provide options that exceed their expectations”.

Our goal with this imitative was to ensure our customers’ experience on our site rivals the best eCommerce sites today. We believe we have achieved that goal. Our mission at Performance Plastics is to bring innovation and value to your business. Our eCommerce platform is going to deliver both these propositions to our customers.

Our updated website is built on a flexible platform that allows you to find what you need quickly. You can search your items by product name or number, read descriptions and view videos of your products in action before your buy.

And now through January 31, 2021, all ecommerce customers will be entered into our drawing for a $100 Amazon gift card.

For more information on EnduroSharp® please visit our website at www.performanceplastics.com/endurosharp.

EnduroSharp® has changed the way aerospace maintenance professionals remove sealants and adhesives from substrates and fasteners. EnduroSharp® tools are made from Torlon®, a high strength polymer, creating a non-metallic gap blade tool that will not damage composite structures during use. The

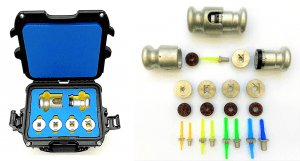

EnduroSharp® has changed the way aerospace maintenance professionals remove sealants and adhesives from substrates and fasteners. EnduroSharp® tools are made from Torlon®, a high strength polymer, creating a non-metallic gap blade tool that will not damage composite structures during use. The  EnduroSharp® has changed the way aerospace maintenance professionals remove sealants and adhesives from substrates and fasteners. EnduroSharp® tools are made from Torlon®, a high strength polymer, creating a non-metallic tool that will not damage composite structures during use. The EnduroSharp® lineup consists of a variety of scraper blades, gap blades, reamers, cutters, bits, and discs for removal of adhesives on aircrafts. The product line also includes a variety of kits containing a selection of parts and sizes.

EnduroSharp® has changed the way aerospace maintenance professionals remove sealants and adhesives from substrates and fasteners. EnduroSharp® tools are made from Torlon®, a high strength polymer, creating a non-metallic tool that will not damage composite structures during use. The EnduroSharp® lineup consists of a variety of scraper blades, gap blades, reamers, cutters, bits, and discs for removal of adhesives on aircrafts. The product line also includes a variety of kits containing a selection of parts and sizes.

EnduroSharp® has changed the way aerospace maintenance professionals remove sealants and adhesives from substrates and fasteners. EnduroSharp® tools are made from Torlon®, a high strength polymer, creating a non-metallic tool that will not damage composite structures during use. The EnduroSharp® lineup consists of a variety of scraper blades, gap blades, reamers, cutters, bits, and discs for removal of adhesives on aircrafts. The product line also includes a variety of kits containing a selection of parts and sizes.

EnduroSharp® has changed the way aerospace maintenance professionals remove sealants and adhesives from substrates and fasteners. EnduroSharp® tools are made from Torlon®, a high strength polymer, creating a non-metallic tool that will not damage composite structures during use. The EnduroSharp® lineup consists of a variety of scraper blades, gap blades, reamers, cutters, bits, and discs for removal of adhesives on aircrafts. The product line also includes a variety of kits containing a selection of parts and sizes.