Torlon (PAI) Polyamideimide is one of the highest performing, melt-processable thermoplastics. Its compressive strength is double that of PEEK when unfiled, and about 40% higher than ULTEM PEI. Torlon is frequently used in medical applications due to its high strength and resistance to deformation. It’s wear resistance adds up to long product life for peristaltic pump rollers and bushings for prosthetics.

Parts manufactured from Torlon plastic will exhibit high levels of tensile and compression strength that ensure good mechanical capability. Additionally, Torlon material provides elevated levels of toughness and rigidity.

In its medical grades, Torlon (PAI) offer high modulus, radiolucency, sterilization-compatibility and high wear resistance, making it ideal for components. PAI’s extremely low coefficient of linear thermal expansion and high creep resistance deliver excellent dimensional stability over its entire service range.

At Performance Plastics, we are experts in injection molding, specializing in high performance plastics. Torlon® is a reactive polymer, which can cause complications during the injection molding process. A specific set of conditions, equipment, and processing procedures must be followed to effectively injection mold Torlon®. Our proprietary tool design software, processes and equipment enable us to injection mold components having complex geometries made from challenging ultra, high-performance thermoplastic materials, and reinforced compounds.

We utilize a unique combination of extensive material knowledge, mold flow analysis, a design system and process expertise to eliminate or minimize the need for secondary operations. Our expertise in process control allows us to effectively injection mold Torlon® in parts with extremely tight tolerances. This gives us the ability to provide an injection molded part made from the highest strength and stiffness of any commercial thermoplastic.

Torlon® is one of the many high performance polymers Performance Plastics specializes. For more information on Performance Plastic’s capabilities, please contact Rich Reed, our Vice President of Sales and Marketing at 513.321.8404 or email at [email protected].

Performance Plastics – Problem Solved – has updated our EnduroSharp® website with a 24/7 ecommerce portal that makes finding and ordering your EnduroSharp® products even easier.

Performance Plastics – Problem Solved – has updated our EnduroSharp® website with a 24/7 ecommerce portal that makes finding and ordering your EnduroSharp® products even easier.

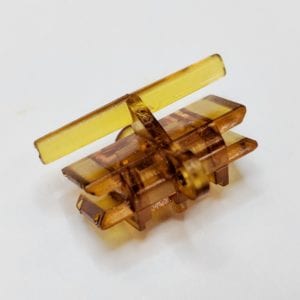

EnduroSharp® has changed the way aerospace maintenance professionals remove sealants and adhesives from substrates and fasteners. EnduroSharp® tools are made from Torlon®, a high strength polymer, creating a non-metallic gap blade tool that will not damage composite structures during use. The

EnduroSharp® has changed the way aerospace maintenance professionals remove sealants and adhesives from substrates and fasteners. EnduroSharp® tools are made from Torlon®, a high strength polymer, creating a non-metallic gap blade tool that will not damage composite structures during use. The

EnduroSharp® has changed the way aerospace maintenance professionals remove sealants and adhesives from substrates and fasteners. EnduroSharp® tools are made from Torlon®, a high strength polymer, creating a non-metallic tool that will not damage composite structures during use. The EnduroSharp® lineup consists of a variety of scraper blades, gap blades, reamers, cutters, bits, and discs for removal of adhesives on aircrafts. The product line also includes a variety of kits containing a selection of parts and sizes.

EnduroSharp® has changed the way aerospace maintenance professionals remove sealants and adhesives from substrates and fasteners. EnduroSharp® tools are made from Torlon®, a high strength polymer, creating a non-metallic tool that will not damage composite structures during use. The EnduroSharp® lineup consists of a variety of scraper blades, gap blades, reamers, cutters, bits, and discs for removal of adhesives on aircrafts. The product line also includes a variety of kits containing a selection of parts and sizes.